TM-9-2330-335-14-P - Page 342 of 640

TM 9-2330-335-14&P

0072-4

0072

INSTALLATION

00072

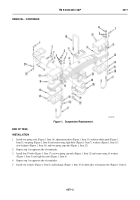

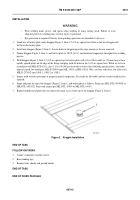

1.

Install two spring seats (Figure 2, Item 16), adjustment plates (Figure 2, Item 15), and four rubber pads (Figure 2,

Items 13 and 14) on spring (Figure 2, Item 12) and secure using eight bolts (Figure 2, Item 11), washers (Figure

2, Item 17), new locknuts (Figure 2, Item 18), and two spring cap ends (Figure 2, Item 8).

2.

Repeat step 1 on opposite side of semitrailer.

3.

Install four U-bolts (Figure 2, Item 19) on two spring cap ends (Figure 2, Item 8) and secure using 16 washers

(Figure 2, Item 9) and eight hex nuts (Figure 2, Item 10).

4.

Repeat step 3 on opposite side of semitrailer.

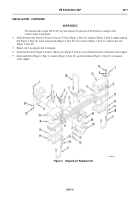

5.

Install two washers (Figure 2, Item 23) and bushings (Figure 2, Item 6) on both sides of trunnion tube (Figure 2, Item 3).

WARNING

The trunnion tube weighs 100 lb (45.4 kg) and requires two persons to lift. Failure to comply could

result in injury to personnel.

6.

Install trunnion tube (Figure 2, Item 3) using two U-bolts (Figure 2, Item 4), wear plate (Figure 2, Item 20), upper

trunnion hub (Figure 2, Item 5), lower trunnion hub (Figure 2, Item 7), four washers (Figure 2, Item 21), and four hex nuts

(Figure 2, Item 22).

7.

Repeat step 6 on opposite side of trunnion.

8.

Install four hex bolts (Figure 2, Item 2) and hex nuts (Figure 2, Item 10) on two bottom brackets of trunnion

center support.

9.

Install eight bolts (Figure 2, Item 1), washers (Figure 2, Item 25), and new locknuts (Figure 2, Item 24) on

trunnion center support.

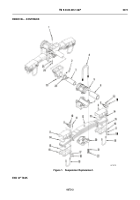

10. Torque suspension nuts to the following in-service DRY torque values:

1-1/8 in.- 12 UNF. . . . . . . . 880 lb-ft (1,193 Nm)

3/4 in.- 16 UNF . . . . . . . . . . . 300 lb-ft (407 Nm)

5/8 in.- 18 UNF . . . . . . . . . . . 180 lb-ft (244 Nm)

11. New replacement installations/hardware should have WET (oiled) fasteners. The following wet torque values apply:

1-1/8 in.- 12 UNF. . . . . . . . . . 670 lb-ft (908 Nm)

3/4 in.- 16 UNF . . . . . . . . . . . 228 lb-ft (298 Nm)

5/8 in.- 18 UNF . . . . . . . . . . . 130 lb-ft (176 Nm)

Back to Top