TM-9-2330-342-10 - Page 397 of 500

FLUID LEAKAGE

It is necessary for you to know how fluid leakage affects the status of the PLST M1076 A1.

Following are types/classes of leakage you need to know to be able to determine the status

of the PLST M1076 A1. Learn these leakage definitions and remember - when in doubt,

notify your supervisor. Equipment operation is allowed with minor leakage (Class I or II).

Consideration must be given to fluid capacity in the item/system being checked/inspected.

When in doubt, notify your supervisor.

When operating with Class I or II leaks, continue to check fluid levels as required in the

PMCS.

Class III leaks should be reported immediately to your supervisor.

1.

Class I :

Seepage of fluid (as indicated by wetness or discoloration) not great

enough to form drops.

2.

Class II:

Leakage of fluid great enough to form drops but not enough to cause

drops to drip from item being checked/inspected.

3.

Class III:

Leakage of fluid great enough to form drops that fall from the item being

checked/inspected.

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

Prior to performing your PMCS, check with your PLL clerk to verify that the latest

publications are being used by the operator and organizational unit.

Listed below are the PMCS procedures applicable to this equipment.

PMCS - BEFORE (WP

0048)

PMCS - DURING (WP

0049)

PMCS - AFTER (WP

0050)

PMCS - WEEKLY (WP

0051)

PMCS - MONTHLY (WP

0052)

PMCS - SEMI-ANNUAL (WP

0053)

Trailers designated or dispatched to transport Class A or B ammunition, explosives,

poisons, or radioactive yellow III materials over public highways require more stringent

inspections.

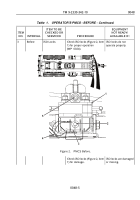

Daily Walk Around PMCS Diagram. This routing diagram will be of help to complete the B,

D, or A PMCS. It shows the trailer PMCS routing track, which matches the sequence of

PMCS to be performed.

TM 9-2330-342-10

0047

0047-3

Back to Top