TM-9-2330-342-23-P - Page 404 of 1348

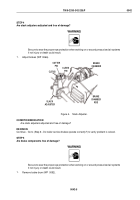

LIFTING DEVICE

BRAKE SHOES

BRAKE

DRUM

Figure 5.

Brake Assembly.

2.

Visually inspect brake shoes, drum and other brake components for excessive wear, broken brake shoe

springs, loose shoes, grooved drums, and other damage that will prevent brakes from releasing.

CONDITION/INDICATION

Are brake components free of damage?

DECISION

Components OK - Go to (Step 6 - Do trailer service brakes operate correctly?) to verify problem is solved.

Components Damaged - Replace damaged component(s) (WP

0072). Go to (Step 6 - Do trailer service brakes

operate correctly?) to verify problem is solved.

STEP 6

Do trailer service brakes operate correctly?

1.

Release brake pedal. Refer to vehicle Operator's manual (WP

0190).

2.

Pull out trailer charge valve in vehicle. Refer to vehicle Operator's manual (WP

0190).

3.

Have assistant turn engine start switch to OFF. Refer to vehicle Operator's manual (WP

0190).

4.

If removed, install brake drum (WP

0092).

5.

If slack adjuster is disconnected, cage brake chamber. Refer to TM 9-2330-342-10 (WP

0190).

6.

If slack adjuster is disconnected, rotate slack adjuster to rod clevis.

7.

If slack adjuster is disconnected, install rod clevis, two pins, and cotter pins on slack adjuster.

8.

If brake chamber is caged, uncage brake chamber. Refer to TM 9-2330-342-10 (WP

0190).

9.

Adjust brakes (WP

0066).

10.

Ensure vehicle is returned to normal operating condition.

11.

Have assistant turn engine start switch to ON. Refer to vehicle Operator's manual (WP

0190).

12.

Push in trailer charge valve in vehicle. Refer to vehicle Operator's manual (WP

0190).

13.

While assistant drives vehicle and then applies brake pedal, observe wheels on trailer with brakes. Refer to

vehicle Operator's manual (WP

0190).

14.

Release brake pedal. Refer to vehicle Operator's manual (WP

0190).

15.

Pull out trailer charge valve in vehicle. Refer to vehicle Operator's manual (WP

0190).

16.

Have assistant turn engine start switch to OFF. Refer to vehicle Operator's manual (WP

0190).

TM 9-2330-342-23&P

0042

0042-6

Back to Top