TM-9-2350-238-20-1 - Page 807 of 1364

TM 9-2350-238-20-1

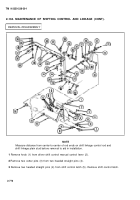

2-135. MAINTENANCE OF IMPACT WRENCH CONTROL HYDRAULIC LINES AND

FITTINGS AND IMPACT WRENCH REGULATOR BALL VALVE.

This task covers:

a.

Removal/Disassembly

c.

Reassembly/lnstallation

b.

Inspection/Repair

INITIAL SETUP

Tools and Special Tools

Automotive maintenance and repair shop equipment: organizational maintenance, common

no. 1 (less power) (item 80, appx B)

•

Torque wrench (0 to 170 ft-lb)

Materials/Parts

Locknut (6)

Lockwasher (4)

Lockwasher (2)

Lockwasher (4)

Preformed packing (8)

Preformed packing (2)

References

TM 9-2350-238-24P-1

General Safety Instructions

•

To avoid injury to personnel, do not tighten or loosen hydraulic fittings when system

is pressurized.

•

Lower the boom to stowed position before doing any maintenance on hydraulic

system.

•

Wipe up spilled hydraulic fluid to prevent injury to personnel.

2-781

Back to Top