TM-9-2350-238-20-1 - Page 817 of 1364

•

To avoid injury to personnel, do not tighten or loosen hydraulic fittings when system

is pressurized.

•

Lower the boom

system.

to stowed position before doing any maintenance on hydraulic

•

Wipe up any spilled hydraulic fluid to prevent injury to personnel.

Install covers on open hydraulic ports, tubes, and hoses immediately after disconnect-

ing them to keep dirt out of hydraulic system.

NOTE

Gain access to hydraulic power supply fittings through the hull well.

1

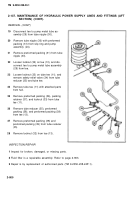

Disconnect flow regulator metal tube assembly (1) from tube nipple (2).

2

Disconnect flow regulator metal tube assembly (1) from tube elbow (3).

3

Loosen tube locknut (4) on tube elbow (3). Remove tube elbow with tube locknut, packing

retainer (5), and preformed packing (6) from impact wrench control (7).

4

Remove preformed packing (6), packing retainer (5), and tube locknut (4) from tube elbow (3).

5

Disconnect spade control valve metal tube assembly (8) from tube elbow (9).

6

Disconnect spade control valve metal tube assembly (8) from valve (10).

7

Loosen tube locknut (11) on tube elbow (9). Remove tube elbow with tube locknut, packing

retainer (12), and preformed packing (13) from impact wrench control (7).

8

Remove preformed packing (13), packing retainer (12), and tube locknut (11) from tube elbow

(9) .

2-791

Back to Top