TM-9-2350-256-10 - Page 56 of 796

HYDRAULIC SYSTEMS

•

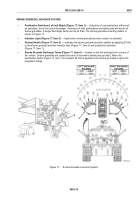

Operator’s Control Valve Manifold (Figure 12, Item 1)

— contains the directional control valves that

allow the operator to control the hydraulic systems.

•

Power Takeoff (PTO) (Figure 12, Item 2)

— mechanically connects the main engine to the mechanical

transmission.

•

Mechanical Transmission (Figure 12, Item 3)

— directs power from the main engine via the PTO

(Figure 12, Item 2) to the hydraulic pump (Figure 12, Item 4).

•

Hydraulic Pump (Figure 12, Item 4)

— provides hydraulic pressure to operate the hydraulic system.

•

Hoist Winch (Figure 12, Item 5)

— capable of handling a maximum load of 25 tons (22.68 metric tons)

with a four part line. Wound with 200 ft (60.96 m) of 0.625-in. (15.88-mm) diameter steel cable with a

useable cable length of 175 ft (53.34 m). Use with hoisting boom.

•

Main Winch (Figure 12, Item 6)

— used for heavy-duty recovery operations. Capable of winching a

maximum load of 45 tons (40.82 metric tons) with four wraps on the drum. Wound with 200 ft (60.96 m) of

1.25-in. (31.75-mm) steel cable with a useable cable length of 174 ft (53 m).

•

Level Winder (Figure 12, Item 7)

— controls the cable placement on the main winch drum.

Figure 12.

Hydraulic System Major Components.

TM 9-2350-256-10

0003

0003-14

Back to Top