TM-9-2350-256-10 - Page 635 of 796

OPERATOR MAINTENANCE

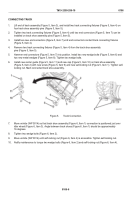

TRACK DISCONNECT AND CONNECT

INITIAL SETUP:

Tools and Special Tools

General mechanic's tool kit

(WP 0135, Table 1, Item 2)

Hand hammer, 10 lb (WP 0132, Table 2, Item 31)

Ratchet, 3/4-in. drive

(WP 0132, Table 2, Item 34)

Socket wrench adapter

(WP 0132, Table 2, Item 3)

Socket wrench set (WP 0132, Table 2, Item 86)

Socket wrench socket, 1-5/16 in. 3/4-in. drive

(WP 0132, Table 2, Item 53)

Tanker bar (crowbar pinch, 5 ft)

(WP 0132, Table 2, Item 12)

Track adjusting wrench

(WP 0132, Table 2, Item 90)

Track connecting fixture Qty: 2

(WP 0132, Table 1, Item 15)

Track end connector puller and pump

(WP 0132, Table 2, Item 46)

Wire brush (WP 0135, Table 1, Item 1)

Materials/Parts

Grease, Automotive and Artillery (GAA) Qty: AR

(WP 0134, Table 1, Item 20)

Materials/Parts (cont.)

Track parts kit (WP 0132, Table 1, Item 41)

Track parts kit (WP 0132, Table 1, Item 40)

Wiping rags Qty: AR (WP 0134, Table 1, Item 57)

Personnel Required

Crewman (3)

References

Chocking vehicle (WP 0103)

Driving the vehicle (WP 0014)

Track tension adjustment (old configuration)

(WP 0109)

Track tension adjustment (new configuration)

(WP 0110)

WARNING

Ensure proper eye protection is worn when hitting metal parts. Metal can break off and act

as a projectile when hit. Failure to comply may result in personnel injury.

NOTE

•

This task is for disconnecting/connecting track between idler wheel and roadwheel

or sprocket and roadwheel. This task applies to track assemblies on both

operator's and mechanic's sides of vehicle.

•

Prior to maintenance, attempt to park vehicle on a level surface and chock the

vehicle (WP 0103).

TM 9-2350-256-10

0106

0106-1

Back to Top