TM-9-2350-311-20-1 - Page 523 of 1275

TM 9-2350-311-20-1

5-1 LUBRICATION

Engine lubrication requirements and procedures are defined in TM

9-2350-311-10

and paragraph 2-15.

5-2 ENGINE INSPECTION

This task covers:

Inspection

References

General mechanic’s tool kit (item 64, Appx H))

TM 9-2350-311-10

. .

Materials/Parts

Equipment Conditlons

Antifreeze test kit (item 63, Appx D)

Air intake grille open (para 11-8)

Engine compartment access cover removed (para 11-5)

Transmission access doors open (para 11-7)

1

2

3

4

5

6

7

8

9

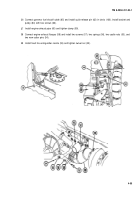

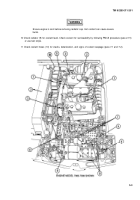

Check gaskets (1), seals (2), and covers (3) for seepage of fuel and oil.

Check for damaged, distorted, or broken hose, tube, and line connectors (nuts, adapters, reduction fittings,

and couplers) (4).

Check fuel hoses, tubes (5), and connectors (4) for cracks, leaks, and seepage of fuel (para 6-9).

Check oil hoses, tubes (6), and connectors (4) for cracks, leaks, and seepage of oil (para 5-3 and 9-4).

Check for stripped or damaged threads on electrical connectors (7), retaining bolts, nuts, and studs. Repair

threads or replace components/items as appropriate.

Check electrical wires, leads, and connectors (8) for cracked insulation, oil, and grease on cables/connectors

(para 8-37).

Check for broken screws and bolts. If broken, drill and remove with screw extractor. Replace broken screws

and bolts.

Check for damaged, burred, pitted, or gummed-up seal, gasket, and preformed packing seats. Clean, remove

burrs, and replace components as required. If damaged beyond repair, or if scope of task is beyond unit

maintenance capability, notify support maintenance.

Check hull engine compartment floor for pools of oil/fuel and coolant.

5-2

Tools

Inspection

Back to Top