TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 456 of 779

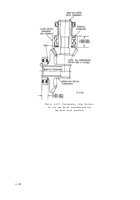

1. Position flyweight housing on advance vane housing.

2. Mate dowel holes (A) with dowel pins (C) and bolt

holes (B) with bolt holes (D). (Refer to note fig. 6-193.)

3. Tap flyweight housing lightly with a soft hammer to

seat dowel pins.

Figure 6-194. Installing flyweight housing .

1. Install two flyweights on adjusting ring with flyweight

pins (A) installed. Flyweights must be installed in their

original positions to assure proper operation.

2. Hook flyweight extension helical springs (B) to

flyweights.

3. Spread flyweights against springs and install oil

control housing in adjusting ring so the slots in control

housing are alined with flyweight pins.

4. Install the assembled adjusting ring, oil control

housing, and flyweights on accessory drive bevel

gearshaft (C). Oil hole (D) in lower groove of oil control

housing must aline with dot in gearshaft (C).

Figure 6-195. Installing advance flyweigh t

adjusting ring and flyweight .

6-162

Back to Top