TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 461 of 779

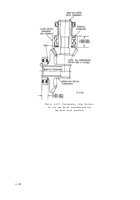

(a) Check fuel level and oil level gage s

(figure 6-199c). Fill supply tank (s) if either gage

indicates less than half full (use oil, specification

MIL-L-45199 (Grade 30) or fuel, specificatio n

VV-L-800) .

(b) Check to insure that the maste r

switch, the oil heater switch, the jog run (clutch

engage) switch, and the motor switch are all in

the “OFF” position and that the speed regulato r

control is at zero (0) .

(c) Turn master switch handle to th e

“ON” position. Note that power indicator ligh t

comes on. If power indicator light does not light,

press the reset buttons. If light still does no t

operate, investigate and correct the deficienc y

before starting .

Figure 6-199c. Test stand heater control an d

supply tanks .

(d) Turn oil heater (thermostat) control ,

figure 6-199c, to a setting of 250 degrees and

turn oil heater switch, figure 6-199b “ON”. The

oil heater indicator lamp will light when th e

heater switch is turned on and will go out when

the oil has reached the selected oil temperature

heater control setting (250 degrees) .

(e) Turn the electronic counter switch ,

figure 6-199b, “ON”. The electronic com -

ponents in the counter will reach operatin g

temperature by the time the test is begun .

(f) Loosen fasteners and remove fue l

injection pump drive housing cover from top o f

test stand. Remove the two bearing caps an d

intermediate bearing support from the mounting

fixture, figure 6-201 .

(g) Install retaining ring on oil retaining

shaft. Install short (stub) end of oil retainin g

shaft in driven (small) end of the advanc e

assembly. Install support over bearing on large

gear end of advance assembly and install ad -

vance assembly in bearing supports of mounting

fixture and secure with hardware remove d

above. Install drive housing cover and secur e

with fasteners .

Caution:

The fuel injector pump advanc e

assembly drive housing cover must always b e

installed and secured before operating test stand.

(h) Push jog run (clutch engage) switch to

engage eddy current clutch and turn spee d

regulator control to obtain advance assembl y

speed of 300 rpm on tachometer. Turn spee d

regulator control clockwise to increase rpm .

(i) Observe oil and fuel pressure in -

dicator gages, figure 6-199b. These gages should

register more than zero (0); however, maximu m

pressures will not be evident until a speed o f

2000 rpm is obtained .

Caution:

Turn master switch handl e

“OFF” if there is no indication of oil or fue l

pressure on the gages. Investigate and correct the

deficiency before starting the test .

(j) Operate test stand at 300 rpm until the

oil temperature dial thermometer (H) stabilize s

at 250 degrees. It may require several minutes to

warm the entire system to operating tem -

perature. Note and record electronic counter (K )

reading (illuminated decimal digits on the fron t

of the counter panel) .

(k) Press oil drain push switch, locate d

immediately

below

the

oil

pressure

indicator

gage. The gage should register zero (0) psi with

the switch depressed. observe the counte r

reading. If the counter has changed more tha n

one (1) degree, the advance assembly require s

adjustment .

(1) Release oil pressure drain switch .

Turn

speed

regulator

control

clockwise

to

in-

crease the speed to 600 rpm. Note and record the

6-167

Back to Top