TM-9-2815-205-24 - Page 146 of 856

TEST AND INSPECTION - Continued

7.

Connect air line to inlet hole in oil cooler. Pressurize oil cooler to 75 PSI (517 kPa).

8.

Submerge oil cooler in a container of water heated to 180°F (82°C). Air bubbles in the water indicate a leak.

Replace any transmission oil cooler with a leak.

9.

Release pressure on transmission oil cooler assembly. Remove plug, reducer bushing (Figure 4, Item 40),

and air hose from transmission oil cooler.

10.

Dry transmission oil cooler with compressed air.

11.

Repeat Steps 6–10 for differential oil cooler (Figure 4, Item 28).

END OF TASK

ASSEMBLY

1.

If removed, install pipe plug (Figure 5, Item 30) in side of oil cooler housing (Figure 5, Item 31) and

draincock (Figure 5, Item 32) in bottom of cooler housing.

2.

Place new gasket (Figure 5, Item 26) on oil cooler housing (Figure 5, Item 31).

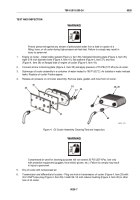

CAUTION

Install oil coolers in correct position to prevent any foreign particles and sludge from

entering engine or transmission. Inlet opening is marked "FROM" on cover and "IN" on oil

cooler. Outlet opening is marked "TO" on cover and "OUT" on oil cooler.

3.

Place four new gaskets (Figure 5, Item 27) around inlet and outlet openings of transmission oil cooler

(Figure 5, Item 29) and differential oil cooler (Figure 5, Item 28).

4.

Place cover (Figure 5, Item 25) over inlet and outlet connectors of oil coolers.

5.

Install four new key washers (Figure 5, Item 24) and four nuts (Figure 5, Item 23) on inlet and outlet

connectors of oil coolers. Do not tighten nuts.

6.

Place assembly of cover (Figure 5, Item 25), transmission oil cooler (Figure 5, Item 29), and differential oil

cooler (Figure 5, Item 28) in oil cooler housing (Figure 5, Item 31).

NOTE

Do not install bolts in locations (C), (D), and (E).

7.

Install cover (Figure 5, Item 25), 17 flat washers (Figure 5, Item 33), 17 new lockwashers

(Figure 5, Item 34), and 17 bolts (Figure 5, Item 35) on oil cooler housing (Figure 5, Item 31). Torque bolts

to 13–17 lb-ft (18–23 N·m).

8.

Torque nuts (Figure 5, Item 23) to 50–60 lb-ft (68–82 N·m). Bend short tangs on key washers

(Figure 5, Item 24) against nuts (Figure 5, Item 23).

TM 9-2815-205-24

0020

0020-8

Back to Top