TM-9-2910-226-34 - Page 134 of 208

TM 9-2910-226-34

CAUTION

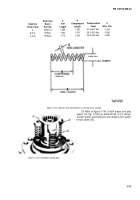

Care should be exercised during installation

of the compensator on code A pumps. The

top of the fuel control link is not secure to the

piston shaft (fig. 3-154). If the top of the link

does not remain engaged in the shaft, the

stop plate will fall into the governor housing,

causing serious damage to the pump.

b. Installation of Fuel Density Compensator

(Code A Pumps).

Refer to figure 3-155, Position a

new mounting gasket (A) on governor housing.

Engage dovetail in torque link stop (B) with

dovetails on guide (C) and compensator plate (D).

All divetails must be properly engaged. Refer to

a

above and figure 3-153 to complete installation of

compensator on injection pump.

NOTE

The stop furnished with a compensator is to

be used with the compensator.

Figure 3-154. installing stop plate and link assembly

(Code A pumps}.

c. Tamper Proof Cover.

Do not install tamper

proof covers. They will be installed after test and

adjustment of pump in paragraphs 3-50 through 3-

58.

d. Installation of Stop Plate and Bridge

Assembly and Governor Housing Cover (code G

pumps).

(1) Refer to figure 3-156. Install plate and bridge

assembly (A) on governor housing and secure with

two capscrews (B), lockwashers (C), and flat washers

(D). Torque tighten screws to 50-60 inch-pounds.

NOTE

The plate and bridge assembly is installed

over the rear pair of tapped holes in the

governor housing.

Figure 3-156. Installing plate and bridge assembly on governor

housing (code G pumps).

(2) Refer to figure 3-157. With throttle lever

secured in full fuel position, insert a feeler gage (A)

between the stop plate (B) and smoke limit cam (C)

and adjust locknuts (D) of droop plate screw to

obtain a preliminary adjustment clearance of 0.020-

inch .

Figure 3-155. Assembling fuel density compensator fuel stop

plates (Code A pumps).

3-88

Back to Top