TM-9-2910-226-34 - Page 127 of 208

TM 9-2910-226-34

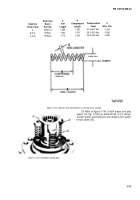

3-42. Installation of Governor Weight and Spider

Assembly.

NOTE

If a new governor weight and spider

assembly was drawn from supply, or if it is a

serviceable part, refer to figure 3-93 and

check friction drive spider slippage; it must

be 48-73 pound-inches.

a.

Refer to figure 3-137. Before installing, check

weight and spider assembly extreme-open position

(A). Extreme-open position (A) should not exceed

3.380 inches. If the open position exceeds this limit,

replace complete assembly. After completing check,

position injection pump housing (B) on an arbor

press and position weight and spider assembly (D)

on camshaft (C). Position remover and replacer over

camshaft and press weight and spider assembly onto

camshaft until flush with shoulder.

Figure 3-137. Checking extreme open position of governor

weight and spider assembly and installing

assembly using remover and replacer.

b.

Refer to figure 3-138. Check camshaft run-out.

Run-out should not exceed 0.003-inch. If camshaft

run-out is between 0.003 to 0.005-inch straighten

camshaft by suitable means. Replace the camshaft if

camshaft cannot be straightened.

Figure 3-138. Checking camshaft run-out.

c.

Refer to figure 3-139. Check sliding sleeve

travel. Remove sliding sleeve from governor

housing, figure 3-89. Position sliding sleeve (A) in

governor weight and spider assembly and rotate

weights (B) completely outward

(a

above) 3.380-inch

(maximum). Sliding sleeve travel must be a

minimum of 0.630-inch. If travel is less than 0.630 -

inch, replace governor weight and spider assembly.

Install sliding sleeve in governor housing, figure 3-

89.

Figure 3-139. Checking sliding sleeve travel.

3-81

Back to Top