TM-9-2910-226-34 - Page 120 of 208

TM 9-2910-226-34

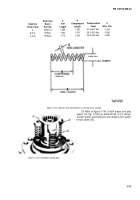

(3) Refer to figure 3-121. Position compressor

and secure with two stud sleeves (A) and hydraulic

head nuts (B). Turn thumb screw (C) clockwise to

compress plunger spring seat. Install spring

retaining ring (D) using suitable pliers. Release

spring tension by turning thumb screw coun-

terclockwise and remove the compressor.

Figure

3-121. Installing tappet spring retaining ring

using compressor.

3-40. Installation of Hydraulic Head Assembly.

NOTE

For proper selection of hydraulic head

assemblies refer to table 3-2.

a. Assembly.

The hydraulic head was inspected

and assembled during repair (para 3-28).

b. Installation.

CAUTION

Do not force the hydraulic head into the

housing. A slight pressure will be required to

seat the preformed packings in the housing.

(1) Refer to figure 3-122. Position hydraulic

head assembly (A) on injection pump housing so

plunger sleeve slot faces opening, and aline slotted

tooth of plunger drive gear with arrow on injection

pump housing. Install four stud sleeves (B) and

hydraulic head nuts (C). Torque tighten nuts to 18-

20 foot-pounds.

Figure 3-122. Installing hydraulic head assembly.

NOTE

Sub-paragraphs (2), (3), and (4) below apply

to code F and G pumps only.

(2) Refer to figure 3-123. Install filter screw

copper gasket (A) and oil filter (B) on filter screw

(D). Apply grease, Federal specification VV-P-236,

to filter screw packing (C), and install on oil filter

screw (D). Install oil filter screw and associated

parts. Torque tighten screw to 20-25 foot-pounds.

Figure 3-123. Installing oil filter.

3-74

Back to Top