TM-9-2910-226-34 - Page 132 of 208

TM 9-2910-226-34

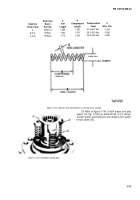

(5) Refer to figure 3-147. Coat end cap gasket with

a thin coat of er, MIL-S-45180 on side facing end cap.

Install end cap gasket (A) and governor end cap (B) and

secure with two machine screws (C) and lockwashers

(D). Torque tighten screws to 50-60 inch-pounds and se-

cure with locking wire (E).

Figure 3-147. Installing governor end cap.

3-44. Installation of Fuel Control Unit

Assembly

NOTE

See figures 3-48, 3-49 and 3-50 for iden-

tification of control units.

a.

Refer to figure 3-148. Position plunger sleeve slot

at bottom of travel, as shown, by pressing down on

sleeve. The fuel control unit lever must be in an idle

position before inserting plunger sleeve pin into plunger

sleeve slot.

b.

Refer to figure 3-149. Install fuel control unit

assembly with new preformed packing, so that plunger

sleeve pin (A, fig. 3-47) engages plunger sleeve slot (fig.

3-148). To check for engagement operate lever back

and forth. Lever should move through about a 500 angle

between and below retainer mounting holes. If this

movement occurs, pin is engaged in sleeve slot. If not,

remove and reinstall control unit and engage plunger

sleeve pin in plunger sleeve slot.

Figure 3-149. Correct installation of control unit in plunger sleeve dot.

C

.

Refer to figure 3-150. Aline the control rod end

with the hole in the control unit lever (A) and install re-

taining pin (B) as shown. Refer to figure 3-151, Install

control unit retainer (A) and secure with two assembled

washer screws (B). Torque tighten screws to 18-23

inch-pounds. Clearance between

unit shaft must be .0100 to .0250

with locking wire (C).

NOTE

Operate fuel control lever

while looking through the

retainer and control

inches. Secure screws

back and forth

overflow valve

discharge hole in the hydraulic head. If the

plunger sleeve is moving, the sleeve pin has

remained properly engaged in the plunger

sleeve slot.

Figure 3-148. Location of plunger sleeve slot.

3-86

Change 2

Back to Top