TM-9-2910-226-34 - Page 32 of 208

TM 9-2910-226-34

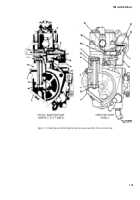

diametrically from the fuel pump end of the hub and

is channeled to receive the ends of the three timing

device springs (B). The new style hubs do not have a

flange and are counterbored to receive the timing

device springs. The springs oppose the flyweight

forces of the weight and spider assembly (AH).

c.

The weight and spider assembly has external

right hand helical splines to mesh with the internal

helical splines of the sliding gear. The splined end is

machined to receive the end play spacer (AE). Three

flyweights are pinned to a flange adjacent to the

splines. The weight and spider thrust plate (AG),

located between the flange and the timing device

housing, carries the back-thrust of the flyweights

and prevents housing wear,

d.

The sliding gear has internal left hand helical

splines at one end and internal right hand helical

splines at the other end and meshes with the external

splines of both the weight and spider assembly and

the timing device hub. Correct assembly of the spline

train is insured by a wide land on both the hub and

weight and spider assembly. The sliding gear has a

missing tooth on each set of internal splines to

receive the wide lands. Three arms extend from the

outer surface of the sliding gear and provide seats for

the three timing device springs. The force on the

springs is controlled by a sliding gear spacer (AF).

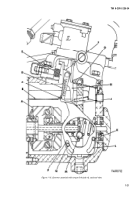

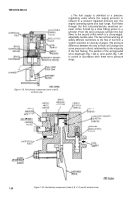

1-17. Fuel Density Compensator (Code F Injection

Pump).

NOTE

The key letters shown below in parentheses

refer to figure 1-15.

a.

The diaphragm housing (BB) is attached to the

top of the governor housing and contains the stop

plate (PP), guide (AA), inlet housing diaphragm

(LL), and related parts.

b.

The fuel inlet housing (DD) attaches to the

diaphragm housing and contains the fuel inlet port

(JJ) and pressure regulator valve (HH).

c.

The pressure regulator valve (HH) is adjusted

by the use of shims. This valve determines the inlet

fuel pressure.

d.

The fuel outlet housing (EE) attaches to the

fuel inlet housing and contains a fuel outlet port

(GG) and an adjustable servo pressure valve (FF).

The fuel outlet housing also has a recess for the servo

spring (CC ).

e.

The servo pressure valve (FF) is adjusted

during calibration of the density compensator to

provide the correct fuel pressure drop across the inlet

housing diaphragm (LL), establishing the stop plate

(PP) travel.

f.

The stop plate guide (AA) provides adjustment

of the fulcrum lever in the injection pump.

g.

The guide bears against the stop plate (PP)

which, in turn, contacts the smoke limit cam (MM).

The guide can be adjusted to move the stop plate

laterally, thereby regulating travel of the governor

fulcrum lever (NN).

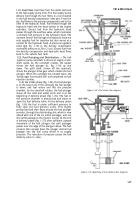

1-18. Fuel Density Compensator (Code B, C, D and

E Injection Pumps).

NOTE

The key letters shown below in parentheses

refer to figure 1-16.

a.

The density compensator housing (BB), and

gasket (Y) are attached to the top of the governor

housing.

b.

The compensator housing cover (EE) and

housing cover gasket (FF) enclose the servo spring

(GG) and the servo pressure well.

c.

The pressure regulating valve (JJ) is adjusted

by the use of shims. This valve determines the servo

system inlet fuel pressure.

d.

The fuel outlet is through an elbow at the right

front of the housing connected by a tube to the fuel

injection pump overflow valve tee.

e.

The servo pressure valve (CC) is adjusted

during calibration of the density compensator to

provide the correct fuel pressure on the piston (H H )

and establish the travel of the stop plate (PP).

f.

The stop plate guide (AA) provides adjustment

of the fulcrum lever in the injection pump.

g.

The guide bears against the stop plate (PP)

which, in turn, contacts the smoke limit cam (MM).

The guide can be adjusted to move the stop plate

laterally, thereby regulating the travel of the

governor fulcrum lever (NN).

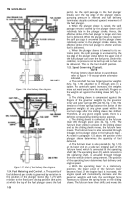

1-19. Fuel Density Compensator (Code A Injection

Pump).

NOTE

The key letters shown below in parentheses

refer to figure 1-17.

a.

The density compensator housing (BB) and

gasket (Y) are attached to the top of the governor

housing.

b.

The compensator housing cover (EE) and

housing cover gasket (FF) enclose the servo spring

(GG) and the servo pressure well.

c.

The pressure regulating valve (JJ) is adjusted

by the use of shims under the plug at the spring end

of the valve. The valve determines the servo system

inlet fuel pressure.

d.

The fuel outlet is through an elbow at the right

front of the housing connected by a tube to the fuel

injection pump overflow valve tee.

e.

The servo pressure valve (CC) is adjusted

during calibration of the density compensator to

provide the correct fuel pressure on the piston (HH)

and establish the travel of the stop plate (PP).

f.

The stop plate guide (AA) provides adjustment

of

-

the fulcrum

-

lever

g.

The guide bears

(AK) and stop plate

the smoke limit cam

justed to move the

regulating the travel

(NN).

in the injection pump.

against the sliding stop weight

(PP) which, in turn, contacts

(MM). The guide can be ad-

stop plate laterally, thereby

of the governor fulcrum lever

1-24

Back to Top