TM-9-2910-226-34 - Page 39 of 208

TM 9-2910-226-34

d.

plus

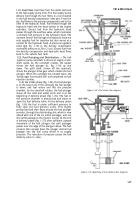

At any position of equilibrium the spring load

the servo pressure is equal to regulator

pressure. The diaphragm (fig. 1-28) or piston (fig. 1-

29) is connected by linkage to a wedge-shaped

movable block which serves to vary the position of

the full-load cam in the injection pump.

Proper

selection of the full-load stop wedge angle and servo

diaphragm or piston spring rate produces the

amount of compensation required to maintain

constant power output over a range of fuels.

e.

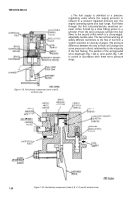

These fuel density compensators are man-

ufactured to provide the fuel compensation for the

multifuel engines. Each fuel injection pump must be

constructed for the particular engine for which it is

designed.

f.

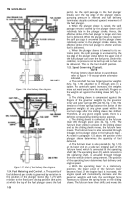

Code G injection pumps are not equipped with

a fuel density compensator. They have a stationary

stop plate and bridge assembly attached to the

governor housing (fig. 1-30). The stop plate and

bridge assembly accomplishes the same function as

the compensator stop plate except it does not

compensate for various viscosity fuels.

1-28.

Fuel Injection Pump Data.

Manufacturer .

Model . . . . . . . . . . . . . . . . . . . . . . . . .

.. . . . . . . . . . . . . . . . . .

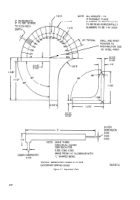

Figure 1-30. Stop plate and bridge assembly (code G).

American Bosch Division

PSB-6A

Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.75 in. (approx)

Width.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.50 in. (approx)

Height:

2910-178-1185 (code A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11.50 in. (approx)

2910 -759 -5419 (code Canal D). . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . 11.50in. (approx)

2910 -103 -2644 (code E)

. . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .11.50 in. (approx)

2910-017-9778 (early code F). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .12.87 in. (approx)

2910-908-6320 (code Band late code F) . . . . . . . . . . . . . . . . . . . . . . . . 11.50in. (approx)

2910-860-2333 (early code G) . . . . . . . . . . . . . . . 9.7in. (approx)

2910-968-6317 (late code G). . . . . . . . . . . . . . . . . . .

9.7 in. (approx)

Name plate location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Top left side of governor housing

Mounting data:

Number of mounting holes

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diameter mounting holes . . . . . . . . . . . . . . . . . . . . . . . 0.406

Governor speed range (on DF-1 fuel):

Idle

Full

load

(code

A)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

650-700

2800

2910-759-5410 (code C and D) . . . . . . . . . . . . . . . . . . . . . . . . 650-700 2600

2910-103-2644 (code E)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 650-700 2600

2910-017-9778 (early code F) . . . . . . . . . . . . . . . . . . . . . . . . . . . 650-700 2600

2910-908-6320 (code Band late code’ F) . . . . . . . . . . . . . . . . . . . . . . .

650-700 2600

(early

code

G).

.

.

.

.

.

.

.

.

.

.

.

.

550-600

2800

2910-968 -6317 (late code G) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 550-600

2800

Rotation (viewed from drive end) . . . . . . . . . . . . . . . . . . . . . . . . .Clockwise

Fuel injection sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1, 5, 3, 6, 2, 4

Delivery valve opening pressure . . . . . . . . . . . . . . . . . . . .250-400 psi

Overflow pressure. . . . . . . . . . . . . . . . . . . . 5 psi max.

Fuel pressures, minimum (after final filter):

700 RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 psi min.

2600 RPM

60 psi min.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel density compensate (all except 2910-860-2333 and 2910-968-6317 pumps):

Pressure regulator valve setting (all fuels) . . . . . . . . . . . . . . . . . . . . . . . . .20-21 psi

1-29. Differences Between Injector Pumps.

Table 1-

the item in the description column is used on that

1 lists the major differences between the pumps used

particular pump.

on the various engines. An X in the column indicates

1-31

Back to Top