TM-9-2910-226-34 - Page 46 of 208

TM 9-2910-226-34

CHAPTER 3

REPAIR OF FUEL INJECTION PUMP

Section I. GENERAL

3-1. Removal and Installation.

Refer to TM 9-2815

210-34 and TM 9-2815-204-34 for instructions

covering the removal and installation of the metering

and distributing fuel injection pump assembly. Refer

to TM 9-2815-210-34P for procurement of cap plug

set, FSN. 5340-450-5718, for covering fuel system

openings.

3-2. Cleaning Before Disassembly.

CAUTION

Absolute cleanliness of fuel pump parts must

be maintained during all disassembly, in-

spection, repair, and assembly procedures.

Dust, dirt, grime, or any abrasive matter

must not come in contact with precision

lapped surfaces of internal parts.

a.

Clean the fuel injection pump externally before

disassembly procedures start. The external cleaning

procedures listed in

b

and c below are recommended

for all fuel injection pumps.

b.

Cover or plug all threaded ports and openings

to prevent entrance of foreign matter during external

cleaning operations.

c.

Use volatile mineral spirits paint thinner or dry

cleaning solvent and scrub the pump with a soft

bristle brush to remove all external accumulation of

grease, dirt, or other foreign matter.

Section Il. DISASSEMBLY OF FUEL INJECTION PUMP INTO SUBASSEMBLIES

3-3. General.

a.

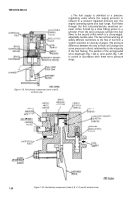

Disassemble the metering and

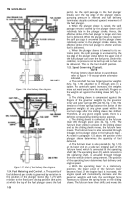

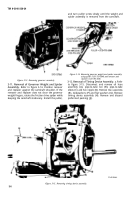

3-4. Removal of Fuel Supply Pump Assembly.

Refer

distributing fuel injection pump in figure number

to figure 3-1. Remove two machine screws (B), lock-

sequence.

washers (C), and remove the fuel supply pump

b.

All packings, gaskets, and sealing rings must

assembly (D). Remove and discard supply pump

be discarded during disassembly to insure

gasket (E).

replacement.

c.

Do not remove any hose or tube fittings unless

there is evidence of leakage or darn age.

3-0

Back to Top