TM-9-2910-226-34 - Page 43 of 208

TM 9-2910-226-34

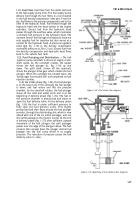

Table 2-1. Special Tools

Section Il. TROUBLESHOOTING

2-6. Purpose.

a.

Information

use of maintenance personnel

in this section is for

in conjunction with,

and as a supplement to the troubleshooting sections

in the pertinent

vehicle and engine technical

manuals. It provides continuation of instructions

where a remedy in the above technical manuals refers

to maintenance personnel for corrective action.

b.

Operation of a deadlined vehicle without a

preliminary examination can cause further damage

to a disabled fuel injection pump and possible injury

to personnel.

By careful inspection and

troubleshooting, such damage and injury can be

avoided and, in addition,

the cause of faulty

operation of a vehicle or fuel injection pump can

often be determined without extensive disassembly.

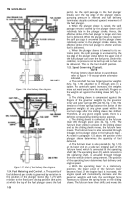

2-7. General Instructions and Procedure.

This

section contains inspection and troubleshooting

procedures to be performed after a fuel injection

pump has been removed from the vehicle and/or

power plant.

a.

Inspection after the fuel injection pump is

removed from the vehicle and/or engine is performed

to verify any diagnosis made when the pump was in

the vehicle,

to uncover further defects, or to

determine any malfunction if the component alone is

received by the maintenance activity. This in-

spection is particularly important in the last case

because it is often the onlv means of determining the

.

malfunction without disassembling the fuel injection

pump.

b.

Troubleshooting a disabled fuel injection

pump after it has been removed from the vehicle

and/or engine consists of subjecting it co tests on a

suitable test stand. This section discusses those

symptoms which can be diagnosed by using the

testing equipment and interprets the results in terms

of probable causes. Information pertaining to this

test is contained in paragraphs 3-49 through 3-52.

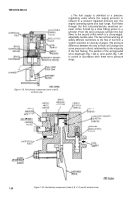

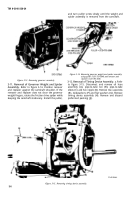

2-8. Procedures.

After a metering and distributing

fuel injection pump has been received by the

maintenance activity for preliminary inspect ion, or if

performance of the pump has been unsatisfactory

due to unknown causes, it must be checked before

installing it on a test stand. This check should in-

clude a search for any binding or broken parts by

rotating camshaft and operating lever. When cause

for failure has been found, fuel injection pump

should be disassembled and repaired

before

proceeding with the tests. Additional operational

tests performed on a damaged fuel injection pump

could only increase the damage. If no cause for

failure is found in inspection, fuel injection pump

should be put on test stand and troubleshooting

performed.

2-3

Back to Top