DMWR-9-2815-220 - Page 23 of 1422

)

)

DMWR 9·2815±220

1-5.

(Cont)

(d±

Valves.

The stem of the intake valve

(±0²

and exhaust vaLve

³49´,

For each cyLInDr,

extends into the Rcker box²

Three nested spr³ngs, coMpressed

between two reta³ne´sµ ¶

·

and secured to the vaLve stem by two coneshaped

¸

locks¹

hold each valve to ³ts seat.

Each eXhaust valve has a pos³t³ve vaLve rotator

º

wh³ch also serves as the lower spring reta³ner»

Valve cLearance adjustinG

screws w³th flat sw³vel pusher pads a´e ¼unted on one end of the va½ve ´ocker

a N¾s ( L and

2µ

.

.

±

¶e·

¿ocker arÀs²

Áorged steel valve rocker ArÀs

¸¹

and

2º

w³th Âoller

cam-Fol½owers a´e used²

Ãhe ´ol½ers are hardened and honed

t

pÄ

º

ovide an eXtremÅ

e½y sÆoth and peÇnent contact surFace

º

È

HoÉlow rocker aNÊ shafts and driLled

passages ³n the Rcker arms convey o³l to aLL ËÌving parts.

»7¼

ÍamshaFts.

ÎheÏ key nuÀbers ³n parentheses below reFer to figure

1-6 ½1/

8

¾

unless otherwise ³ndicatedÐ

(a)

Ñamshaft asseÀblies.

Îhe leFt and right caÀshaft asseÀbLies

¿3

and

1À}

are ÒuntedÓ one on each bankÔ on the cyÕ³nders and operate the valve ÖchanÅ

ism.

Îhe caÀshaFts are ho½Õow to p´ovide oiL passages For p×Øssure Lubrication

to tÙe valve parts and to perÚ³t defLect³on when the cylinde´s fiÛeº

ÎubUlar

¼lded rubber

encLose the camshafts between cyL³ndersº

:liIYÁ

Üb±

ÍaÝhaFÞ dr³ve.

ßach caàhaft ³s dr³ven by the accessory drive gear

¸1ÂÃÄ

accessory dr³ve gearshaFt asseÀbly

Å8ÆÇ

camshaFt dr³ve bevel gearshaft

ÈÉÊË

camshaFt dr³ve gearshaFt

½5ÃÌ

and camshaft dr³ven gear

Í4Î

tháugh an ³ncl³ned

qu³ÕL type camshaFt dr³ve shaft

½6Ï.

Îhe dr³ve shafts can be ´e¼ved to peâãit

SäåPrate R_tæ

·

Qçèéheê camshaFës FOr eng³ne ti!ìingº

When camshaFts are

correctLy pos³t³oned ³n relation to íÙe cranksîaFtï the drðñe sòafóô have differõ

ent nuÀber of spl³nes on each end and th³s allows them to be ³nserted ³n the

"

ö

÷ams øa Ft beveÕ gùúrû haüts w³ýhout d°þsturbi ng re'l ÿtionshiĀ beātĂăeĄn

¸

ąaĆshaftć

-·

and crankshaft.

(

1/±)

s.±²

cnG,³

Lul1C

²³

/±7²³& sySrT

I>

Å8Æ

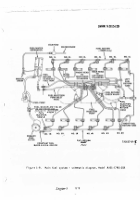

Ĉubrication sYstem. ĉ³gure

1-É

²

²³ s´

Ð

o

L

de l

S

g ´ µ

ybrÑtaTÒEÓsÔÕÖ

ncv¶i

·- ¸A

D

'×

Ø

/´

µ ¶·

J¹

º:» ¼½w ¾.6¿ €ÀÁ,Âã ÄÅÆÇ ÈÉ ÊËÌ

(a}

Ċeneral.

Îhe ċ³n pressure o³l puÀp draws o³l fČm the pressure

o³L pump coÀpartÀent ³n the o³L pan.

Ãh³s compartment is fed by the scavenge

o³l pučp wh³ch pĎcks

ď

up oil frOm the Front end of the oiL pan

Đ

and by o³l wh³ch

drains ³nto the pressure compartđĒnt from the cover of the pressure pump comē

partment and the reserve compartment.

Ãhe pressurized oil is forced through

the eng³ne oiL coolers and oiL Filter to the engine oiL galLer³esÔ bearĔngs,

turbosuperchargersĕ Fuel inJection puÀpÔ and to the p³ston o³l sĖrayer nozzlės²

Ãhese noZĘLes are Located ³n the crankcase below eacÙ cyL³nder and provide a

cont³nuous o³l spray to the pistons and cyl³nder waLls.

a

pressuÛe ´egulator

vaęveï located on the rĎght s³de oF the crankshaFt damper and oĎl f³Õter hous³ngĚ

³s ³nFLuenced by the pressěre in the Ĝĝin bear³ng oiL galLery and returns the

incoming eĞcess unFiLtered o³l to the oiL pan.

(bğ

ĠĎL ġanĢ

The oiL pan is a one-p³ece

aLuĆinuÀ alLoy castģng dĔvided

into a pressure o³L pĤđp coÀpartĥĦntħ oiL reserve coÀpartÀėntĚ and tÙe suÀp

,

.

µ

comĨaÂtđĒnt at the f´ont of the panº

ĩored passages froÀ each of ĪÙe coĆpartīnts

ÙÚ

O

J

'

'

´

'

µ

)

'

S¶

¶1(

Û /¹¹

Back to Top