DMWR-9-2815-220 - Page 328 of 1422

)

±

I

DMR 9·2815±220

5-37.

(Cont)

(a)

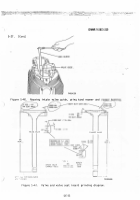

Seat dressing±

A 45 DeGree an

²

³le stone must be UseD to GrInD the

exhaust vaLve seat, an´ a 15 deGree anGµe GrfOd¶nG stone must Be used FoR the

iNtake vaLve seats·

¸ress the seat on The

insert wIth the stone usinG a vaµve

¹seat GrindInG MachIne.

Aºter DressinG tHe seat oº tHe Insert, inspect vaµve con»

T¼ct as DescrIbeD In ParaGrapH 5½3

?

¾ b (4)

_

5/¿58).

(b) Seat widtHÀ When 360 deGre

²

Áo

³´

ct is oBtained, narrow tHe seat on

tÂe insert to tHe wIDtH speciFIeD in FiGUre

Ã

5

½

41 (5/¿95) by GrInDinG the Inner

waµL and eXposeD Face oF tHe Insert to tHe anGµes sPecIFIedÄ

KeeP vaµve seat

area as near as possIBLe to tHe cenÅer oF tHe vaµve ºace.

Vaµves sHouµD never

seat at tHe top or bottoÆ oº tHe vaµve Face area·

(3)

VaLves.

ÇiscarD vaµves tHat have warpeD¾ cracÈeD¾ PitteDÉ or burned

Faces.

Aµso DÊscarD vaLves HavInG baDLy Pitted, scored¾ or scratcHed steMs or

ËocÈinG Grooves·

ÌeFace sµÊGhtµy pitteD or Burned vaµves tHat do not have 3Í0

deGrees oº contact to LiÆIts sPeciÎIeD in FiGure 5½41 (5/Ï95)À

¸IscarD vaLves

tÐat cannot be rEFaced to these LimIts·

CHecÑ vaµve µenGth From seat contact to

tiP oF steM aFter GrIndiNG¾ as sHown in ºiGure 5Ò41 (5/¿95)·

¸iscarD vaµve iF

µenGtH is not withÓn the LIÔIts sPeciFIed·

(4)

CYµinder Bore·

Cyµinder Bores sHouµd Be re

$

rounD to tHe neÕt oversIze

aÖcordinG to overs×ze standards µisted in tØBµe 5½10 Ù5/

¿53

) when bore DiÚnsions

aRE not witHIn LiÔitsÀ

AFter tHe cyµinDer bore has Been reGrounD oversIZe¾ the

cÛµInDer asseMBLy IdentiFication nuÜer (ºiG·

5Ò32) (5/157) sHouµD Be cHanGed in

aÖcordance with the part nuÔBers µIsted In T¼bµe 5Ý¿1 (5/Þ57) to reFµect tHe

reGround bore sIze·

ßhe cyLInDer asseMBLy shouLd aLso Be reGrounD oversIZe when

tÐe cyµInDer Bore is FounD to Have excessIve scratchesÉ scorinGà rinG r

á

iDGeÉ or

wÐen tHe bore Is GLaâeã or smootH.

ALµ cyµinder bores Must Be honeD aºter GrInd»

IäG and/or BeFore new pIston rinGs arE InstaLµedÀ

åyµInDer Bore honInG speciFI»

cations and recoæçendeã ProcedurEs are outµIned Beµowè

/

(a)

CyµInder Bore honinG séecIFications·

i

G

²

êross hatch anGµe to Be 35

/

Grees oFF tHe HorIâontaL·

2

Cross hatch to Be cUt uniForÔµy

ë

in Both DirectIons.

3

Cross hatch to Be cµeanÒcut¾ But not ìsHarP, and ºree From torn or

Fíµded ÔeîaµÀ

4

ïhe MicroÝFinIsh rouGHness sHoUµD averaGe Between 35 and 45 micro»

I NcHes¾ ðs (rootñmeanÝsquare DeviatIon From tHe òan)¾ as óasUreD on a Proô

FiLometerÀ

5

ïHe pLateau area sHouLD Be ¿/2 to 2/3 oF tHe surºace area.

Í

ïHe pµateau shouLd Be ºree ºroM BurnIshed or Gµazed surFacesÀ

7

ïHe surFaõö ÷ust be ºree oº eMbedded PartIcLesÄ

5/¿9Í

µ

Back to Top