DMWR-9-2815-220 - Page 333 of 1422

)

±

.

±² ³

·´

5-37.

(Cont)

•

.²

µ

¶

¸¹

º

»¼

½

³ ´µ

. :

¾¿ÀÁ

Â-Ã

DMWR 9-2815-220

!

Stamp the Necessary Mtch Mrks on both the cyliNder and cover to

iNdIcaTe a ±Atched asse²bly.

(3)

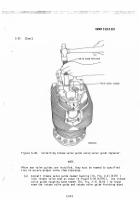

Valve RocKe³ ´µ¶s·

/

(a¸

Bearing sLeeves·

RepLace worn o³ daMGed bushinG - type valve

roc¹e³ a³º bea³»nG s¼eeves UsiNG a s½¾table arbor press¿

,

I

NOTE

ÀeariNG sleeves ±ust be flush to 0.01ÁiNch below surface at both Ends

µ

Ä

of ³ocKer a±Ã

ÄF spLit type beariNG sLeeve is Used, the spLIt oF the

bea³¾nG mÅst not be iN LiÆe wÇth the oil hoLeÃ

Èb¸

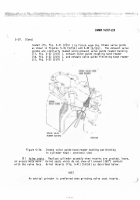

´djustiNg screw.

Replace the adJustÉnG screw wheN threads A³e

Ê

trËpPed

Ì daºaGeDÍ

or wHen sc³ew binds iN the ³ocker ar²¿

´Lso repLace adÎUstInG

screw when swiveL pad does Not rotate freeÏy oÆ the screwÃ

e·

´ssembLy·

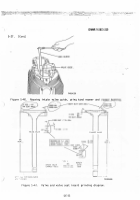

ÈÐ) Ñeneral asseºblY Òroceduresà Óefer to paraG³aph 5-8 È5/ÔÐ ) for GeneraL

asse²bly proceDUres.

È2)

´ssembLÕ Örocedures¿

Óefer to

tM

9×2815-220Ø34.

(±)

V

l

²1 Ae

a1tly, TeLT

·

f

T

for ±E b

F ²h³ i´T&A µ ¶u pz· wITh ¸U ¹ cC for º »-

1¼d TH³

cU

½r³. Ro ¾9 ¿ ÀÁoWÂ OÃÄ

:

ae

Å1ÆÇyÈ

TÉLT

v³´µ

for lÊ By

•¶J ¸g

1k

¹

oË

Cl ºd»r ¼n

noZsÌ ÍÎ

AnD APly¼Ng

60 ½

S Ï1Ã

a

Ïr³1·Ð To

C¾ ¿ ºDÀr ÁÂ

Ñr ÒÓ Ô¼²h

Ã

1ÕÖ

Ä

off× Ø rÙT• fÚÛ ÜrÝ ÏÞ

A

L Å ÆÇ È'

Ï1¼ » lß 1eà áf â³

L

ÉÊ ËÌ

ãä× åA

U

æ ç exAè

pz· TÜ

ÍÎ

Ãf lé

u

fêë ìl'í or îeAT. %f ïðñ

u

frò

ÏÐÑ

rejec,

i

±E

u

fÚò óôõeAT× Aö÷

Ò

To

2Ó

Ïä leøAge »

ÔÕ

1ùöoúû

mÖ × ØÙÚÛÜ Ý

k tT² ³f´

Þ

ßà

á

s

;

•

r

Wâ

:

( 4¶

fRcSsu E

/£ãä Roåæ ç èéê

hë ìí@îïðñ

wFò

SFµC

óô

/Jf

¶d· )3¸

õö÷S

:

. Nu ¹AKaº»

øùúûüý

¼

½¾¿ÀÁ

Back to Top