TB-9-2320-302-13-P-1 - Page 44 of 380

TB 9-2320-302-13&P-1

OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS) - CONTINUED

0009 00

0009 00-2

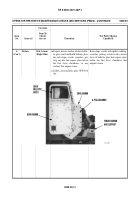

FRONT

AND LEFT

SIDE

1

Before

Front Armor

a. Inspect front and cowl armor panels

for damage or loose or missing

mounting hardware.

Any panel or armor plate is damaged,

bent out of shape, misaligned, loose or

missing, or mounting bolts are loose or

missing.

b. Inspect front and cowl armor panels

for areas of rust or corrosion.

Any corrosion where area is unsound

and small pin holes are present, or a

rusted through condition is present.

c. Inspect front and cowl armor panels

for cracks near or elongation of bolt

holes.

Any cracks that are longer than 1” or

two consecutive bolt holes that are elon-

gated.

d. Inspect front and cowl armor panels

for any holes or gouges.

Any complete penetration of the armor

(hole in the armor) or multiple gouges

1/4” or deeper within 3” of each other.

e. Inspect windshield ballistic glass

mounting hardware for damage,

loose, or missing mounting hardware.

Any ballistic glass mounting hardware

is damaged, loose, or missing, or

mounting bolts are loose or missing.

f. Inspect exterior surface of wind-

shield ballistic glass for rock chips,

cracks, scratches, pitting, any hits that

expose glass below the first layer,

cloudiness, or any stickers that impair

vision.

Rock chips, cracks with spider webbing,

scratches, pitting, or hits in the exterior

layer of ballistic glass that expose glass

below the first layer, cloudiness that

impairs vision.

g. If dirty, clean windshield ballistic

glass (WP 0010 00).

Item

No.

Interval

Location

Procedure

Not Fully Mission

Capable If:

Item To

Check/

Service

Back to Top