TB-9-2350-368-25 - Page 16 of 120

TB 9-2350-368-25

2-2

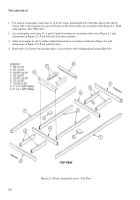

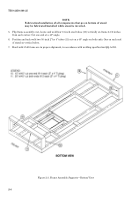

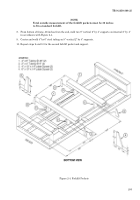

1. Cut ends of rectangular steel tubes (1, 2) at 45° angle, final length to be 96 inches (243.8 cm) and 50

inches (127.0 cm) respectively. Lay steel tubes on flat level surface in accordance with Figure 2-1. Weld

ends together. (See TM 9-237.)

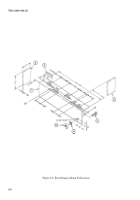

2. Lay rectangular steel tubes (3, 4, and 5) inside box frame in accordance with art in Figure 2-1 and

dimensions in Figure 2-2. Tack weld all steel tubes together.

3. Align steel angles (6 and 7) within welded framework in accordance with art in Figure 2-1 and

dimensions in Figure 2-2. Tack weld all joints.

4. Hard weld, if all items are in proper place, in accordance with welding specification QQ-A-250.

Figure 2-1. Frame Assembly Layout—Top View

Back to Top