TM-3-1040-279-12-P - Page 34 of 389

TM 3-1040-279-12&P

2-7 SPECIAL INSTRUCTIONS. (cont)

Table 2-1. Operator Preventive Maintenance Checks and Services (cont)

Item

No.

6

(cont)

Interval

BEFORE,

AFTER

BEFORE,

AFTER

BEFORE,

AFTER

Location

Item to Check/

Service

Fog Oil Pump

Assembly

(cont)

Procedure

(Cont)

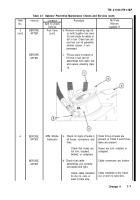

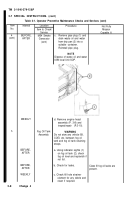

Check that hoses are

torn, cracked, twisted,

or collapsed.

Check that cable

assemblies are correctly

connected and tight.

Check cable insulation

for dry rot, cuts, or

wear to bare wire.

Check fog oil strainer

screens and clean as

required:

Remove cap screw (1),

with preformed

packing and strainer

screen (2) from

strainer assembly (3).

Clean screen with dry

cleaning solvent and

rags (Items 4 and 11,

App E).

Check to ensure that

preformed packing on

cap screw is not cut or

torn. Notify organiz-

ational maintenance if

damaged.

Install strainer screen

(2) into strainer as-

sembly (3) and secure

with cap screw (1).

Ensure preformed

packing is in good

condition. Replace if

necessary. Do not

over-tighten.

Not Fully

Mission

Capable If:

Hoses are torn, cracked, or

collapsed.

Cable connectors are broken.

Cable insulation is dry rotted,

cut, or worn to bare wire.

2-10

Change 4

Back to Top