TM-3-1040-279-12-P - Page 36 of 389

TM 3-1040-279-12&P

2-7 SPECIAL INSTRUCTIONS. (cont)

Table 2-1. Operator Preventive Maintenance Checks and Services (cont)

Item

No.

7

(cont)

a

Interval

BEFORE,

AFTER

AFTER

d.

BEFORE

e.

BEFORE,

AFTER

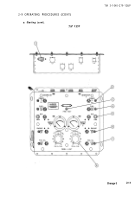

Control Panel

Assembly

a.

Location

Item to Check/

Service

Air

Compressor

Assembly

(cont)

Procedure

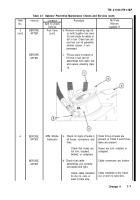

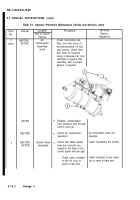

Check mechanical felt

filter: turn filter cover (1)

counterclockwise 1/4 turn

and remove. Check filter

and clean as required

using compressed air only.

Reinstall or replace filter

assembly with on-board

spares, if required.

Not Fully

Mission

Capable If:

Release condensation

from pressure tank through

control valve (2).

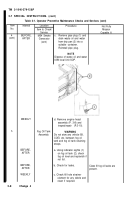

Check air compressor

operation.

Check that cable assem-

blies are correctly con-

nected to the back of the

control panel and are tight.

Check cable insulation

for dry rot, cuts, or

wear to bare wire.

Air compressor does not

operate.

Cable connectors are broken.

Cable insulation is dry rotted,

cut, or worn to bare wire.

2-10.2

Change 4

Back to Top