TM-5-2350-378-24-P - Page 236 of 790

TM 5--2350--378--24&P

0013 00--11

FRONT CORNER (LEFT OR RIGHT) RAISES IN SPRUNG, BUT NOT UNSPRUNG MODE --

Continued

0013 00

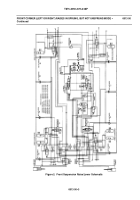

Figure 6. Sprung/Unsprung Control Valve Linkage

SPRUNG/UNSPRUNG CONTROL VALVE LINKAGE ADJUSTMENT

WARNING

Do not operate ejector when personnel are in bowl. Do not work in

bowl unless ejector lock is engaged. Failure to comply may result in

severe injury or death to personnel.

NOTE

All control rods are adjusted the same way. This procedure

covers the SPRUNG/UNSPRUNG control rod.

Note position of control valve plunger (Figure 6, item 1) when SPRUNG/UNSPRUNG

control lever is in NEUTRAL (off) position.

NOTE

Normal control valve plunger travel is 9/32 in. (7 mm).

Remove cotter pin (Figure 6, item 2), straight pin (Figure 6, item 5), and clevis (Figure 6,

item 6) from control valve plunger (Figure 6, item 1). Discard cotter pin (Figure 6,

item 2).

Loosen jam nut (Figure 6, item 7). Turn clevis (Figure 6, item 6) clockwise to shorten

rod (Figure 6, item 3); counterclockwise to lengthen rod (Figure 6, item 3).

Hold measuring device (Figure 6, item 4) on face of SPRUNG/UNSPRUNG control

valve. Have assistant move SPRUNG/UNSPRUNG lever between SPRUNG and

UNSPRUNG mode. Measure distance of plunger travel. Adjust length of rod (Figure 6,

item 3) travel to desired distance by turning clevis (Figure 6, item 6), as necessary.

Coat threads of rod (Figure 6, item 3) with sealing compound primer and sealing

compound. Tighten jamut (Figure 6, item 7) against clevis (Figure 6, item 6).

Connect clevis (Figure 6, item 6) to control valve plunger (Figure 6, item 1) with straight

pin (Figure 6, item 5) and new cotter pin (Figure 6, item 2).

Back to Top