TM-5-3805-254-14-P-2 - Page 192 of 894

TRUCK SERVICE MANUAL

BRAKES-AIR

shown in Fig. 9.

Brake lining on a bellmouthed brake

drum will make contact only on the inner surface of the

drum.

In addition to cutting the braking surface to a

minimum, it will also cause uneven and rapid wear.

Fig. 8 Bulged Brake Drum

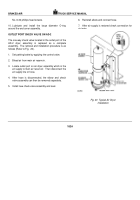

Fig. 9 Bell-Mouthed Brake Drum

Scored drums are the result of worn lining to the point

where drum to shoe contact is made or an accumulation

of small steel particles imbed themselves in the brake

lining (Fig.

10).

The steel particles form a tough scale

which is sometimes harder than the drum.

As a result, in

either case deep grooves are formed in the friction

surface of the drum.

Brake drum scoring never improves but continually gets

worse until both the lining and the brake drum are

useless.

Attempting to reline brakes without turning

scored brake drums is impractical because the rough

drum surface will quickly destroy new lining and make

effective braking impossible.

Brake lining in an eccentric or out-round drum cannot

make full contact with the drum, thus resulting in rapid or

uneven lining wear and could even cause brakes to seize

or chatter.

Maximum allowable out-of-round or

eccentricity should be .

004".

If inspection shows that any of the foregoing conditions

exist, the brake drum should be either turned or

replaced.

To assure a balanced braking system, always

install turned or new brake drums in pairs on each axle.

Remember that each time brake drums are turned, less

metal remains to absorb the heat developed by braking

action.

Brake drums containing less metal will operate at

higher

Fig. 10 Scored Brake Drum

temperature.

As a result, brake fade, slow recovery and

erratic action will be more noticeable.

Also, the

extremely high temperatures will not only shorten lining

life, but also can cause heat checks and cracks to form

on the inner surfaces of the drums. These conditions will

become progressively worse until finally the drums will

fail.

To recondition a brake drum in a lathe, the drum must be

mounted so that it is centered.

Use the proper size cone

to provide accurate centering.

Turn drum, taking only

light cuts and remove just enough material to clean up

drum.

Then grind the finish surface if grinder is available

or use emery cloth on a straight piece of wood and polish

the drum friction surface.

NOTE: Brake drums that are otherwise in good condition

can be turned in a lathe.

However, it must be remembered that the recommended

rebore limit for brake drums 14 inches diameter and

under must not exceed .060" diameter (total cut) and

brake drums with a diameter over 14" may not be

increased more than .080" diameter (total cut).

Brake drums should be cleaned thoroughly with a steam

cleaner or hot water.

Do not use a solvent which leaves

an oily residue. If inspection shows the drums may be

used without remachining, rub the friction surface with

fine emery cloth or sandpaper to remove any foreign

deposits.

If the drum has been reconditioned, clean the

friction surface with fine emery cloth or sandpaper and

wash. Next, examine very carefully to see that no metal

chips remain in the drum.

BRAKE SHOES AND LINING

The brake shoe is that part of the brake mechanism to

which the brake lining is attached.

The brake shoe with

the lining retards the rotation of the wheel when forced

against the drum during brake applications.

Brake shoes must be true and of correct radius.

188

Back to Top