TM-5-3805-254-14-P-2 - Page 189 of 894

BRAKES-AIR

TRUCK SERVICE MANUAL

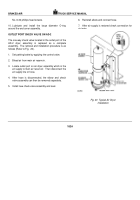

Fig. 2 Exploded View of Front Brake Group

Legend for Fig. 2

1

WASHER, adjuster spacing

2

BUSHING, camshaft bracket

3

BRACKET, w/BUSHING, camshaft

4

CAMSHAFT

5

WASHER, camshaft spacing

6

BRACKET, brake chamber

7

PLATE, w/BRACKET, backing

8

PIN, shoe anchor (4)

9

RETAINER, anchor pin

10

LINING, brake

11

SHOE, w/LINING

12

SPRING, shoe return

13

RETAINER, brake shoe roller

14

ROLLER, brake shoe

15

LUBRICATOR,

1/8 straight

16

ADJUSTER, slack, assy

17

CHAMBER, brake, assy

18

PIN, brake chamber yoke

PIN, cotter

19

YOKE, brake chamber

20

PIN, brake shoe guide

WASHER, guide pin outer

WASHER, bowed

WASHER, guide pin inner

WASHER, "C"

1.

Position the truck on floor stands and remove wheel

and drum.

2.

Remove dust shields from rear axle brake groups.

3.

Remove the shoe return spring or springs.

4.

Remove "C" washers from shoe guide pins (if so

equipped).

5.

Remove anchor pin retainers, washers, felt retainers

and felts from anchors.

6.

Remove brake shoes.

To remove brake shoes from

rear brake groups, the anchors must be removed.

To do so, remove anchor pin retainers, felt retainers,

felts, lock wire and lock screws or pins (Figs. 3 and

4).

7.

The brake shoe anchors can now be re moved from

the front axle brake group by removing nut and

lockwasher from anchor then forcing the anchor from

the backing plate.

8.

Remove cam roller assemblies from brake shoes.

9.

Remove clevis pin, connecting brake chamber push

rod to slack adjuster.

Remove lock ring, cotter key

or capscrew holding the slack adjuster to end of the

camshaft.

Remove slack adjuster.

10. Push or tap the camshaft out of the spider or backing

plate bracket.

Be sure to keep spacer washers in

proper order for correct reassembly.

11. Inspect camshaft bushings and replace if necessary.

CLEANING AND INSPECTION

Clean all brake parts in cleaning fluid and wipe

them dry.

It is particularly important that brake shoes

with lining removed be cleaned thoroughly.

Use steam,

solvent or wire brush to remove all traces of rust and

corrosion.

If any rust or corrosion is allowed to remain

on the lining surface or shoe table of the shoes, it is

possible that the lining may crack while being attached to

the shoe.

Brake drums should be thoroughly cleaned.

See "Brake

Drums".

REASSEMBLY

After the various components of the brake

assemblies have been serviced, the brakes may be

reassembled by reversing the disassembly procedure.

It is recommended that newly installed brake

lining be circle ground before installing the brake drums.

Circle grinding the lining to fit drum assures full contact

between lining and drum.

The brake lining may either be circle ground

either when lining is installed on shoes (See "Brake

Lining and Shoes") or after shoes are installed on

vehicle.

The brake shoe grinder which mounts on the

spindle is used after installing shoes with new lining (Fig.

5).

The grinder rotates about on its axis, the grinding

head equalizes the distance between the two brake shoe

lining surfaces and the drum surface.

Grind the new

lining approximately .070" less than the inside diameter

of brake drum.

Make certain that the brake is fully

released before grinding.

185

Back to Top