TM-5-3895-372-20 - Page 199 of 694

TM 5-3895-372-20

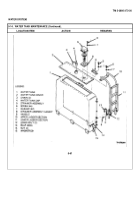

Table 6-1.

Admix Systems Troubleshooting Procedures (Continued).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3.

LIQUID ADMIX FLOWS TOO QUICKLY:

Step 1.

Check for 14%1

- 15Y2 psi (100-107 kPa) air pressure.

See Malfunction No.

1.

Step 2.

Check for relief valves venting at 15 psi (103.5 kPa).Bleed pressure.

Remove

vent and install test gage with 1/8 in.

thread.

Check pressure.

If gage is faulty, replace.

Otherwise, adjust relief valve (para 6-17).

Step 3.

Check flowmeter calibration (see para 6-10).

Replace faulty flowmeter (see para 6-10).

4.

LIQUID ADMIX FLOWS TOO SLOWLY OR NOT AT ALL:

Step 1.

Check for 14%’

- 15% psi (100-107 kPa) air pressure.

See Malfunction No.

1.

Step 2.

Check for leaks.

Tighten loose connections.

Replace leaking lines or valves (para 6-14).

Step 3.

Check for dirt or sediment blocking system.

Flush system.

First use cleaning agent recommended by admixture

manufacturer.

Then use clean water.

Step 4.

Check for blocked strainer.

Clean strainer (para 6-8).

Step 5.

If temperature is below 320F (0°C) check for frozen admix lines.

a.

Open draincocks.

b.

Apply heat to melt ice.

c.

When ice is melted, close draincocks.

Step 6.

Check flowmeter calibration (para 6-10).

Repair or replace flowmeter.

(See para 6-11 or 6-10).

6-5

Back to Top