TM-5-5420-202-20-2 - Page 244 of 734

TM 5-5420-202-20-2

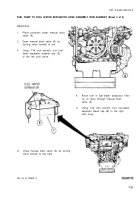

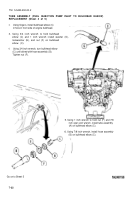

FUEL BACKFLOW VALVE REPLACEMENT (Sheet 3 of 4)

10.

11.

12.

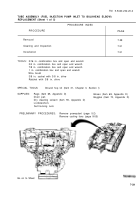

CLEANING AND INSPECTION:

Using pipe wrench, remove elbows (B) and

(P) from fuel backflow valve (L).

Using pipe wrench (L), remove tee (Q) from

fuel backflow valve (L).

Using adjustable wrench on tee (Q), use

9/16 inch combination wrench to remove

reducer (G).

Dry cleaning solvent P-D-680 is toxic and flammable.

To prevent personal injury, wear

protective goggles and gloves and use only in a well-ventilated area. Avoid contact with skin,

eyes, and clothes and don’t breathe vapors.

Do not use near open flame or excessive heat. The

flash point for Type #l Dry Cleaning Solvent is 100°F (38°C) and for Type #2 is 138°F (50°c).

If you become dizzy while using cleaning solvent, get fresh air immediately and get medical aid.

If contact with eyes is made, wash your eyes with water and get medical aid immediately.

1. Using clean cloth and solvent, clean fittings and mounting hardware thoroughly.

2. Inspect fittings and mounting hardware for nicks, cracks, wear or thread damage

Replace if required.

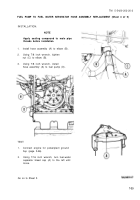

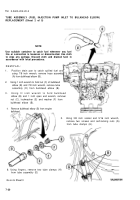

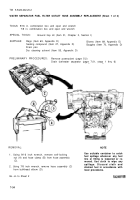

INSTALLATION:

NOTE

Coat threads of fittings with sealing com-

pound before installation.

1.

Using pipe wrench, install elbows (A) and

(B) to fuel backflow valve (C).

2.

Using adjustable wrench, install tee (D)

to fuel backflow valve (C).

3.

Mount fuel backflow valve assembly (E)

to bracket.

Go on to Sheet 4

7-27

Back to Top