TM-5-5420-202-20-2 - Page 567 of 734

TM 5-5420-202-20-2

FUEL TANK REPAIR (Sheet 2 of 2)

Dry cleaning solvent P-D-680 is toxic and flammable. To prevent personal injury, wear

protective goggles and gloves and use only in a well-ventilated area Avoid contact with skin

eyes, and clothes and don’t breathe vapors. Do not use near open flame or excessive heat. The

flash point for Type #1 Dry Cleaning Solvent is 100°F (38°C) and for Type #2 is 138°F (50°C)

If you become dizzy while using cleaning solvent, get fresh air immediately and get medical aid.

If contact with eyes is made, wash your eyes with water and get medical aid immediately.

CLEANING:

1.

Using dry cleaning solvent,

Wipe dry with cloths.

2.

Using sandpaper, sand area

after sanding.

REPAIR:

clean area around crack to remove all traces of dirt and grease.

around crack for proper adhesion of sealer. Wipe with cloth

1.

2.

3.

4.

5.

6.

7.

Using ruler, mark spot to bore hole 1/2 to 1 inch from ends of crack on a line with crack.

Coat drill bit with grease to minimize amount of metal chips falling into fuel tank.

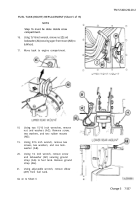

Using drill, bore hole about 1/2 to 1 inch from visible ends of crack as shown.

Clean crack and surrounding area with cloth dampened in dry cleaning solvent. Wipe dry.

Do not allow fingerprints, oil, or moisture on cleaned surface.

NOTE

Do not apply sealer at temperatures below 45 degrees F. Sealer will cure in

approximately 24 hours at room temperature.

Mix accelerator and sealer in container.

Apply 3/16 inch thickness of sealer to cleaned surface and at least 1/2 inch beyond crack.

Install powerplant (page 5-14).

End of Task

7-332

Back to Top