TM-55-1425-289-14

TM-55-1425-289-14 - Page 44 of 61

TM 55-1425-289-14

Table 6-4.

Continued

Item

No. Required

Application

B

4

Blocks, lumber, 4- x 6- x 120-inch. Locate

one in front of the front and intermediate

wheels and in back of the front and rear

wheels. Toenail each end to the side blocking

with two 60d nails.

C

8

Cleats, lumber, 4- x 6- x 18-inch.

Locate

against blocks as indicated in figure 6-7,

and secure each cleat to side blocking with

ten 60d nails.

D

8

Padeyes. Required on the floor of the vessel

if proper D-rings or deck tiedown fittings

are not available.

E

2

Wire rope, 5-8-inch, formed into a complete

loop around the tiedown ring. Secure with

clamps (item I below).

F

2

Wire rope, 518-inch, formed into a complete

loop.

Secure with clamps (item I below).

G

2

Wire rope, 518-inch, formed into a complete

loop.

Secure with clamps (items I below).

At-

tach to the front tiedown ring on the fire

unit, on each side of the vehicle.

H

2

Wire rope, 5/8-inch; form the first cable into

a complete loop between the rear right-hand

golf club clevis, routed through cable guides

at the top corner, and the left-hand padeye;

form the second cable into a complete loop

between the left-hand golf club clevis,

routed through cable guides at the top cor-

ner, and the right-hand padeye.

Secure each

with four clamps (item I below).

I

28

Clamps, 5/8-inch. Secure to items E through

H.

J

16

Place one thimble at each tiedown provision

and turnbuckle.

K

8

Turnbuckles, 3/4- x 18-inch.

Apply turn-

buckles between wire rope and padeyes.

Tighten to even tension between all turn-

buckles.

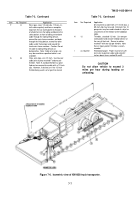

Table 6-5.

Bill of Materials for Blocking and

Tiedown of M35 Truck, with OMTS Shelter, in

General Cargo Vessel (Fig 6-8)

Approximate

Item

Description

Quantity

Lumber

Douglas-fir, or comparable:

Straight-grain, free from material

defects; Fed Spec MM-L-751H:

2- x 4-inch

8 linear ft

2- x 12-inch

44 linear ft

4- x 6-inch

62 linear ft

Nails

Common steel; flathead; bright or

cement-coated; Fed Spec FF-N-

105B:

12d

32

30d

as required

60d

16

Wire rope

6 x 19, IWRC; improved plow

steel; preformed, regular-lay; Fed

Spec RR-W-410C: 5/8-inch

80 ft

Clamps

Wire rope, U-bolt clips, saddled,

single-grip; steel, Crosby heavy-

duty, or equal; Fed Spec FF-

C-450D: 5/8-inch

16

Table 6-6.

Application of Materials for Blocking and

Tiedown of M35 Truck, with OMTS Shelter, in

General Cargo Vessel (Fig 6-8)

Item

No. Required

Application

A

4

Lumber, 2- x 12- x 96-inch.

Pre-position on

vessel deck so that two pieces are under the

left rear wheels and two pieces are under the

right rear wheels parallel to the long axis of

the truck.

B

4

Lumber, 2- x 12- x 36-inch. Pre-position on

vessel deck so that two pieces are under each

front wheel parallel to the long axis of the

truck.

C

2

Side blocks.

Each to consist of 4- x 6- x

108-inch lumber.

Center one piece against

the outside of the left and right rear wheels.

D

2

Side blocks.

Each to consist of 4- x 6- x 48-

inch lumber.

Center one piece against the

outside of each front wheel.

E

4

End blocks.

inch lumber.

Locate one piece forward of the

front and intermediate wheels and behind

the front and rear wheels.

Toenail each end

of the side block with two 60d nails.

F

8

Backup cleats.

Each to consist of one piece

of 2- x 4- x 12-inch lumber.

Locate one on

top of items C and D against the joint of

each item E.

Nail to items C and D with four

12d nails per block.

G

as required

Bracing, lumber, 4-inch x 6-inch x random

length, cut-to-fit.

Place the ends against the

side blocking and blocking of other cargo, or

the side of the ship or other ship's structure.

Nail with 30d nails where appropriate.

H

as required

Blocks.

4-inch x 6-inch x random length,

cut-to-fit.

Place blocks around the truck and

against other blocking, on the side of the

ship or other ship's structure as appropriate,

to assist in holding the bracing in place.

J

4

Wire rope, approximately 20 feet each.

Form a complete loop through the truck tie-

down provision and appropriate deck padeye

or D-ring.

Pull the wire rope taut and secure

it with clamps (item K).

K

16

Clamps.

Use four clamps to

secure each

item

J.

Details for placement of clamps are pro-

vided in figure 5-3 or 7-4.

Material for these items are not included in table 6-1.

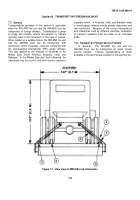

6-6.

Landing Ships, Landing Craft, and Amphibious

Vehicles

When the ROLAND missile system is moved

for extended distances or through rough waters,

blocking and tiedowns must be used.

In most cases, the

vessels are equipped with turnbuckles with a sheep's

foot on one end that fits into a deck cloverleaf; where

not provided, a suitable substitute may be used.

6-7.

Lighter Aboard Ship (LASH)

a.

General.

When transporting the ROLAND

missile system by LASH-type ships, securement with

blocking and tiedowns is required.

Barge stability is

6-9

Back to Top