TM-9-2320-209-34-2-3 - Page 256 of 592

TM 9-2320-209-34-2-3

d.

Cleaning. There are no special cleaning

ing procedures given in Part 1, para 1-3.

NOTE

Clean all parts before inspection

e.

Inspection and Repair.

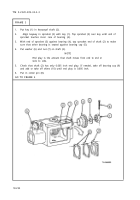

FRAME 1

procedures needed. Refer to clean-

and before assembly.

1.

Check that shafts (1 through 6) have no cracks or distortion. Use magnaflux

if available.

If shafts are cracked or damaged, get new ones.

2.

Check that all machined surfaces and threads are not worn or damaged. If

parts are damaged, get new ones.

3.

Check that splines on shafts (3 and 6), flanges (7 and 8), and sliding gear

(9) are not worn, scored, burred, bent, twisted or rough. Raised metal,

nicks or scratches must be taken off with honing stone and shafts polished

using crocus cloth. If more repair is needed, get new parts.

4.

Check that splines on shafts (3 and 4), flanges (7 and 8),

(9) join together and move easily with one another. Minor

smoothed with a honing stone, then polished with a crocus

repair is needed, get new parts.

GO TO FRAME 2

and sliding gear

damage can be

cloth.

If more

18-245

Back to Top