TM-9-2320-272-23-3 - Page 578 of 1469

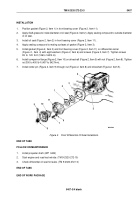

INSTALLATION

1.

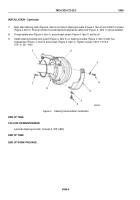

Position gasket (Figure 2, Item 1) in front bearing cover (Figure 2, Item 11).

2.

Apply GAA grease to inside diameter of oil seal (Figure 2, Item 2). Apply sealing compound to outside diameter

of oil seal.

3.

Install oil seal (Figure 2, Item 2) in front bearing cover (Figure 2, Item 11).

4.

Apply sealing compound to mating surfaces of gasket (Figure 2, Item 3).

5.

Install gasket (Figure 2, Item 3) and front bearing cover (Figure 2, Item 11) on differential carrier

(Figure

2,

Item

4) with eight washers (Figure 2, Item 6) and screws (Figure 2, Item 7). Tighten screws

93

to

120

lb-ft (126 to 163 N·m).

6.

Install companion flange (Figure 2, Item 10) on driveshaft (Figure 2, Item 5) with nut (Figure 2, Item 8). Tighten

nut 300 to 400 lb-ft (407 to 542 N·m).

7.

Install cotter pin (Figure 2, Item 9) through nut (Figure 2, Item 8) and driveshaft (Figure 2, Item 5).

9

10

11

8

7

6

1

2

3

4

5

M7094DAA

Figure 2.

Front Differential Oil Seal Installation.

END OF TASK

FOLLOW-ON MAINTENANCE

1.

Install propeller shaft. (WP

0402)

2.

Start engine and road test vehicle. (TM 9-2320-272-10)

3.

Check differential oil seal for leaks. (TM 9-2320-272-10)

END OF TASK

END OF WORK PACKAGE

TM 9-2320-272-23-3

0407

0407-3/4 blank

Back to Top