TM-9-2320-272-23-3 - Page 692 of 1469

ASSEMBLY - Continued

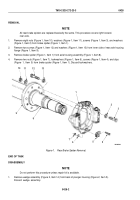

NOTE

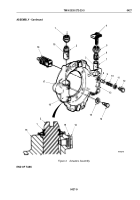

Apply a light film of GAA grease to all parts prior to assembly.

7.

Align guide groove (Figure 3, Item 3) of two adjusting plungers (Figure 3, Item 7) with adjusting pawl holes

(Figure 3, Item 8) of adjusting plunger housing (Figure 3, Item 13).

8.

Install adjusting plungers (Figure 3, Item 7) in adjusting plunger housing (Figure 3, Item 13).

9.

Position two adjusting sleeves (Figure 3, Item 6) on adjusting plunger (Figure 3, Item 7).

NOTE

Adjusting pawls have teeth and flats on one end and chamfered edge on the other end. When

performing Step (4), ensure adjusting pawl is positioned with chamfer toward sleeve to align

pawl and sleeve teeth.

10.

Install two adjusting pawls (Figure 3, Item 9) and springs (Figure 3, Item 10) in adjusting plunger housing

(Figure 3, Item 13) with two gaskets (Figure 3, Item 11) and hollow screws (Figure

3,

Item

12). Tighten hollow

screws 15 to 20 lb-ft (20 to 27 N·m).

11.

Using adjusting bolt (Figure 3, Item 4), rotate adjusting sleeve (Figure 3, Item 6) and check for proper teeth

meshing. If teeth are properly meshing, a clicking sound and ratchet feel will be indicated. Remove adjusting

bolt.

12.

Position inner lip of two plunger seals (Figure 3, Item 5) over adjusting sleeves (Figure 3, Item 6). Using hammer

and 1-3/4 in. (44.45-mm) wrench socket, seat outer ring of plunger seals in adjusting plunger housing

(Figure

3,

Item

13).

TM 9-2320-272-23-3

0427

0427-7

Back to Top