TM-9-2320-272-23-4 - Page 769 of 1393

CLEANING, INSPECTION, AND REPAIR

WARNING

Solvent cleaning compound is flammable and toxic. Do not use near an open flame and

always have a fire extinguisher nearby when solvents are used. Use only in well-ventilated

places, wear protective clothing, and dispose of cleaning rags in approved container. Failure

to comply may result in damage to equipment, injury, or death to personnel.

1.

Clean all items with solvent cleaning compound before inspection (Volume 5, WP

0819).

2.

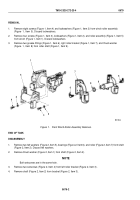

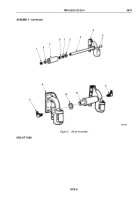

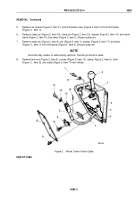

Inspect side roller shaft (Figure 3, Item 4) for cracks and wear. Measure outer diameter of shaft at bushing

(Figure 3, Item 6) contact points. Discard if cracked or if any outer diameter is less than 0.994 in. (25.25 mm).

3.

Inspect bushings (Figure 3, Item 6) for scoring and wear. Measure inner diameter of bushings. Discard if scored

or inner diameter is more than 1.010 in. (25.65 mm).

NOTE

Perform Steps (4) and (5) only if bushings are to be replaced.

4.

Using arbor press and mandrel, remove two bushings (Figure 3, Item 6) from roller (Figure 3, Item 7). Discard

bushings.

5.

Install two bushings (Figure 3, Item 6) on roller (Figure 3, Item 7).

6.

Inspect thrust washers (Figure 3, Item 5) for cracks and wear. Measure thickness of thrust washers. Discard

if cracked or if thickness is less than 0.040 in. (1.02 mm).

7.

Inspect roller shaft (Figure 3, Item 1) for cracks, scoring, and wear. Measure diameter where bearings

(Figure

3, Item 2) contact shaft. Discard if cracked, scored, or any measured diameter is less than 1.495

in.

(37.97 mm).

8.

Inspect thrust washers (Figure 3, Item 3) for chips, cracks, scoring, and wear. Measure thickness of thrust

washers. Discard if chipped, cracked, scored, or thickness is less than 0.052 in. (1.32 mm).

9.

Inspect two bearings (Figure 3, Item 2) for chips, pitting, cracks, and damaged cage. Discard if chipped, pitted,

cracked, or cage is damaged.

TM 9-2320-272-23-4

0679

0679-4

Back to Top