TM-9-2320-272-24-2 - Page 246 of 991

TM 9-2320-272-24-2

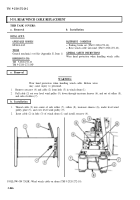

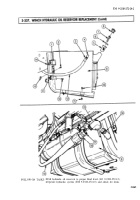

3-335. TRANSMISSION PTO-TO-HYDRAULIC PUMP PROPELLER SHAFT UNIVERSAL

JOINT

MAINTENANCE

THIS TASK COVERS:

a. Disassembly

b. Inspection

INITIAL SETUP:

c. Assembly

APPLICABLE MODELS

M925/A1/A2, M928/A1/A2, M929/A1/A2,

M930/A1/A2, M932/A1/A2, M936/A1/A2

TOOLS

REFERENCES (TM)

TM 9-2320-272-24P

EQUIPMENT CONDITION

General mechanic ’s tool kit (Appendix E, Item 1)

Transmission PTO-to-hydraulic pump propeller

shaft removed (para. 3-334).

MATERIALS/PARTS

Dust cap assembly (M939/A1)

(Appendix D, Item 103)

Dust cap assembly (M939A2) (Appendix D,

Item 104)

Lubricating oil (Appendix C, Item 50)

a. Disassembly

NOTE

This procedure covers maintenance for both universal joints,

1.

Position propeller shaft (1) in soft-jawed vise so end yoke (2) moves freely.

2.

Remove four lockrings (6) from universal joint (5).

NOTE

Do not drop bearing cups. Needle bearings inside are very small

and can easily be lost.

3.

Remove two bearing cups (4) and end yoke (2) from propeller shaft yoke (3).

4.

Remove two bearing cups (7) and universal joint (5) from propeller shaft yoke (3).

5.

Remove grease fitting (8) from universal joint (5).

6.

Remove dust cap (10) and slip yoke (13) from propeller shaft splines (9).

7.

Remove dust cap (10), nylon washer (11), and felt washer (12) from slip yoke (13). Discard felt

washer (12), nylon washer (11), and dust cap (10).

8.

Remove grease fitting (14) from slip yoke (13).

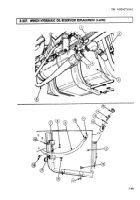

b. Inspection

1.

Inspect bearing cups (4) and (7) for worn or missing needle bearings. Replace needle bearings if

worn or missing.

2.

Apply a few drops of lubricating oil in bearing cups (4) and (7). Using finger, roll needle bearings

around to check for free movement. Replace bearing cup(s) (4) or (7) if needle bearing movement is

rough or uneven.

3.

Inspect end yoke (2), propeller shaft yoke (3), slip yoke (13), and universal joint (5) for scoring,

burrs, cracks, and bends. Replace part(s) if defective.

3-854

Back to Top