TM-9-2320-272-24-2 - Page 670 of 991

TM 9-2320-272-24-2

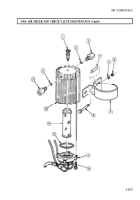

3-466. WATER SEPARATOR MAINTENANCE

THIS TASK COVERS:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Cleaning and Inspection

INITIAL SETUP:

APPLICABLE MODELS

M939A2

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

MATERIALS/PARTS

Fluid pressure kit (Appendix 128)

Crease (Appendix C, Item 32)

REFERENCES (TM)

TM 9-2320-272-10

TM 9-2320-272-24P

EQUIPMENT CONDITION

Parking brake set (TM 9-2320-272-10).

Air reservoirs drained (TM 9-2320-272-10).

GENERAL SAFETY INSTRUCTIONS

When cleaning with compressed air, wear eyeshields

and ensure source pressure does not exceed 30 psi

(207 kPa).

a. Removal

1.

Disconnect two air lines (1) from adapters (2) on water separator (3).

2.

Remove two adapters (2) from water separator (3).

b. Disassembly

1.

Remove body (4) from bowl (12).

2.

Remove stud (9), filter (8), louver (7), gasket (6), and O-ring (5) from body (4). Discard

filter (8), gasket (6), and O-ring (5).

3.

Remove automatic drain valve (10) and O-ring (11) from bowl (12). Discard O-ring (11).

c. Cleaning and Inspection

1.

For general inspection instructions, refer to para. 2-15.

2.

Clean bowl (12) with warm water and all other parts with soap and warm water.

WARNING

Eyeshields must be worn when cleaning with compressed air.

Compressed air source will not exceed 30 psi (207 kPa). Failure to

do so may result in injury to personnel.

3.

From inside body (4), blow out internal passages with compressed air.

d. Assembly

1.

Coat lip of automatic drain valve (10) with grease and install new O-ring (11) and automatic drain

valve (10) in bowl (12).

2.

Install new O-ring (5), new gasket (6), louver (7), and new filter (8) on body (4) with stud (9).

3.

Install body (4) on bowl (12).

3-1278

Back to Top