TM-9-2320-272-24-3 - Page 106 of 799

TM 9-2320-272-24-3

4-62. FAN DRIVE CLUTCH (M939A2) MAINTENANCE

THIS TASK COVERS:

a.

Disassembly

b.

Cleaning and Inspection

c. Assembly

INITIAL SETUP:

APPLICABLE MODELS

M939A2

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Micrometer (Appendix E, Item 80)

Snap gauge (Appendix E, Item 123)

Torque wench (Appendix E, Item 144)

Arbor press

Vise

MATERIALS/PARTS

Fan drive repair kit (Appendix D. Item 108)

Adhesive sealant (Appendix C, Item 4)

GAA grease (Appendix C, Item 28)

Rags (Appendix C, Item 58)

Antiseize tape (Appendix C, Item 72)

REFERENCES (TM)

TM 9-2320-272-10

TM 9-2320-272-24P

EQUIPMENT CONDITION

Fan clutch removed (para. 3-74).

GENERAL SAFETY INSTRUCTIONS

l

Return spring is under compression and may

cause injury if not properly removed.

l

When cleaning with compressed air, wear

eyeshield.

a. Disassembly

1.

2.

3.

4.

5.

6.

7.

8.

9.

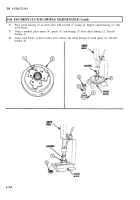

Install bracket (4) in soft-jawed vise, with housing (3) facing up.

Place prybar between studs (1) to keep housing (3) from turning.

Remove cap (2) from housing (3).

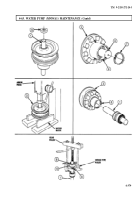

Remove locknut (5), spring washer (6), spacer (7), housing (3), pulley (8), and spacer (9) from

shaft (10). Discard locknut (5), spring washer (6), and spacer (7).

WARNING

Return spring, located between thrust cap and piston, is under

compression. Wear eyeshields and follow disassembly instructions

carefully, or injury to personnel may result.

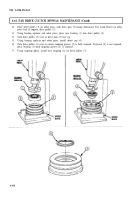

Install housing (3), facing up, in a soft-jawed vise.

Remove six screws (11) from housing (3), leaving two screws (11) installed opposite one another.

NOTE

Assistant will help with steps 7 and 8.

While assistant holds down thrust cap (12), alternately loosen and remove two remaining

screws (11) from housing (3).

Slowly release and remove thrust cap (12), return spring (13), clutch facing (14), and spacer (15)

from housing (3). Discard clutch facing (14) and spacer (15).

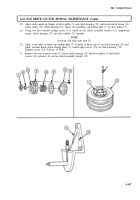

Remove piston (16) from housing (3) as follows:

a. Install cap (2) on housing (3), and place housing (3) on bracket (4).

b. Wrap rag around base of shaft (10).

4-370

Back to Top