TM-9-2320-273-34 - Page 405 of 801

TM 9-2320-273-34

(3)

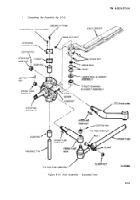

Aline the knuckle pin flats to mate with the draw key holes, and tap the knuckle pin

through the knuckle yoke: axle center and the thrust bearing from the top or bottom side.

NOTE

The draw keys are installed one from

each side of the axle center. Do not

install both keys from the same side.

Before setting the draw keys, center

the knuckle pin to equalize the gap

between the upper and lower gap

mounting surfaces.

(4)

Install the draw keys so that the flat on the key mates with the corresponding flat on

the knuckle pin.

(5)

Install the draw key nuts and torque between 30-45 Ib-ft (41-61 N·m).

d.

Knuckle Clearance (End Play) Check.

Measure the clearance between the top face of the upper

axle surface and the lower face of the knuckle pin boss as follows,

(1)

Set up a dial indicator graduated in thousandths with the mechanical clamp or magnetic base

affixed to the knuckle spindle such that the knuckle can be turned freely (fig. 9-12).

Figure 9-12. Dial Indicator Setup.

9-13

Back to Top