TM-9-2320-273-34 - Page 399 of 801

TM 9-2320-273-34

9-5. Cleaning.

a. Parts having ground and polished surfaces such as the knuckle pins, knuckle pin sleeves, bearings,

and spindles, should be cleaned in dry cleaning solvent (item 12, App B).

NOTE

Do not use gasoline or a hot solution

tank. Do not use water and alkaline

solutions such as sodium hydroxide,

orthosilicates, or phosphates.

b.

Parts should be thoroughly dried immediately after cleaning. Use soft, clean, lint-free, absorbent

paper towels or rags. Do not dry bearings by spinning with compressed air.

9-6. Inspection.

Perform a careful and thorough visual inspection of all components, prior to reassembly,

as follows.

a.

Steering Knuckle and Knuckle Pin.

(f) Inspect the steering knuckle thrust bearing, wheel bearing cones and cups. Replace if

rollers or cups are worn, pitted, or damaged in any way. If wheel bearing cups are to be replaced, remove

from hubs with a suitable puller. Avoid the use of drift and hammers as they may easily mutilate cup bores.

(2) Inspect the steering knuckles and replace if indications of weakness or excessive wear is

found.

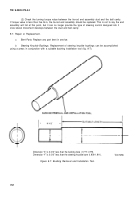

(3) Check knuckle pin for excessive wear. Compare with correct specification.

(4) Check upper knuckle pin grease seal for rips, tears and excessive wear. Do not remove upper

grease seal from steering knuckle counterbore unless replacement is necessary. If seal must be replaced,

follow removal procedures (9-4c).

(5) Remove lower knuckle pin seal from thrust bearing case and inspect seal for wear, rips and

tears.

(6) Check thrust bearing and lower seal gaskets for wear. Some axles may employ an integral

gasket in the lower seal or thrust bearing.

(7) Check knuckle pin bushings for flaking and galling. Compare with correct specification. Do

not remove bushings from steering knuckle unless replacement is necessary.

b.

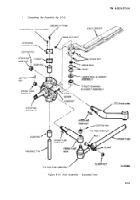

Tie-rod End.

(1) Check seals visually for any indications of damage. Also check to make sure seal is securely

seated on socket. Tie-rod ends should be replaced if seals are damaged or loose.

CAUTIO N

Do not attempt to salvage damaged ends

by repacking and replacing the boot seal

on non-greasable ends.

9-7

Back to Top