TM-9-2320-273-34 - Page 394 of 801

TM 9-2320-273-34

9-2. On-Equipment Testing. Any indication of looseness in the total steering linkage arrangement

under normal steering loads is sufficient cause to immediately check all pivot points for wear, regard-

less of accumuIated mileage.

a. Steering linkage pivot points should be check each time the axle assembly is lubricated. If

any indication of lateral movement is found, tie rod ends should be removed for inspection. Loose-

ness at the steering linkage pivot points can be visually detected during movement of the vehicle

steering wheel in dry park position.

b.

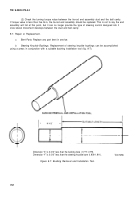

Inspection of knuckle end play without removing the hub and drum from the axle can be

accomplished by raising axle wheel end off floor, attaching the dial indicator to the axle center and

positioning the indicator plunger on the upper knuckle pin cap with its line of action parallel to the

knuckle pin center line. Perform steps (3) thru (5) (para 9-8d). On axles that have been installed

under a vehicle, the end play may increase to a maximum of 0.065 inch at which time it will be

necessary to re-shim end play back to 0.005-0.025 inch using the above procedures.

9-3. Removal. Procedures for removal of the front axle assembly from the vehicle are given in para-

graph 2-14.

9-4. Disassembly.

a. Removing the Wheel and Hub.

Use the following procedure to remove the wheel and hub

from the steering knuckle.

WARNIN G

Do not attempt disassembly or knuckle

repair with the vehicle supported by

jacks only. Severe injury can result

from an inadequately supported vehicle.

9-2

Back to Top