TM-9-2320-273-34 - Page 401 of 801

TM 9-2320-273-34

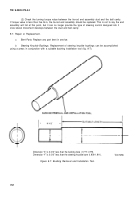

(7) Press worn bushings out of the knuckle using the small end of the bushing removal tool in

the bushing.

(2) Place a replacement bushing on the small diameter end of the tool and press it into the

steering knuckle in three steps as follows. This allows the bushing to allne itself with the bore.

(a) Press the bushing into the knuckle about 1/8 inch and then relieve pressure.

(b) Press the bushing in another 1/2 inch and relieve the pressure.

(c) press the bushing in until it is flush with the surface of the upper seal counterbore, for

the top, or with the inside surface of the lower knuckle boss for the bottom.

(d) Line ream upper and lower bushings to 1.787-1.789 in.

c. Corrosion Prevention.

Parts that have been cleaned, dried, inspected and are to be immediate-

ly reassembled should be coated with light oil to prevent corrosion. Spindles, knuckle pins or sleeves

that are to be stored for any length of time should be treated with rust preventative, wrapped in oiled

paper and boxed to keep dry and clean.

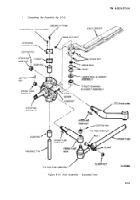

9-8. Assembly

Incorrect installation of the grease seals

could result in premature lubricant con-

tamination and a need for more frequent

lubrication and service intervals. For

maximum operating service from the

front axle assembly, install the seals by

the following procedures.

a.

Upper Grease Seal Installation.

(1) place the steering knuckle, bottom side up, in a vise equipped with soft metal jaws and lock

securely.

(2) With the top end of the knuckle held firmly in this position, place the new grease seal over

the knuckle counterbore with the rubber lip facing up.

9-9

NOTE

Back to Top