TM-9-2320-361-20 - Page 427 of 1207

TM 9-2320-361-20

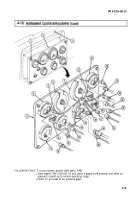

4-10. INSTRUMENT CLUSTER REPLACEMENT

This task covers:

a. Removal

c. Assembly

b. Disassembly

d. Installation

INITIAL SETUP:

APPLICABLE MODELS

All

MATERIALS/PARTS

Antiseize tape (Appendix C, Item 27)

REFERENCES (TM)

TM 9-2320-361-10

EQUIPMENT CONDITION

●

Parking brake set (TM 9-2320-361-10).

●

Battery ground cable disconnected (para. 4-48).

●

Air reservoirs drained (TM 9-2320-361-10).

GENERAL SAFETY INSTRUCTIONS

Do not disconnect air lines before draining air

reservoirs.

TM 9-2320-361-20P

a. Remova l

1. Turn four lockstuds (1) ¼ turn to left and pull instrument cluster (2) away from instrument

panel (3).

NOTE

Tag each wire, air tube, and drive shaft for installation.

Location of gages on instrument cluster may vary for M44A2

series trucks, Install gages in their original locations.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Disconnect tachometer drive shaft (19) from tachometer (6).

Disconnect speedometer drive shafl (12) from speedometer (7).

WARNING

Do not disconnect air lines before draining air reservoir. Small

parts under pressure may shoot out with high velocity, causing

injury to personnel.

Disconnect air line (26) from air pressure gage (27).

Disconnect wire plug (16) from wire connector (17).

Disconnect wire plugs (5) and (25) from engine temperature gage (4).

Disconnect wire plugs (10) and (11) from oil pressure gage (9).

Disconnect wire plugs (20) and (18) from fuel gage (21).

Disconnect wire connector (14) from high beam indicator (15).

Disconnect wire connectors (13) and (23) from two indicator lamps (8).

Disconnect wire plug (22) from battery and generator gage (24).

Remove instrument cluster (2) from instrument panel (3).

4-16

Back to Top