TM-9-2320-361-34 - Page 315 of 764

TM 9-2320-361-34

15-1.

CARGO BODIES MAINTENANCE

(Contd)

WARNING

All personnel must stand clear during lifting operations. A swinging

or shifting load may cause injury to personnel.

NOTE

Assistant will help guide cargo body during lifting operations.

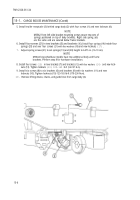

8. Remove cargo body (1) and place on wooden supports.

NOTE

Perform steps 9 and 10 if replacing cargo body.

9. Remove cargo body tailgate (3) (TM 9-2320-361-20).

10. Remove cargo body dropside (2) (M35A2C) (TM 9-2320-361-20).

11. Remove one frame sill (4) from each frame rail (5) for inspection.

I

b. Cleaning and Inspection

I

1.

For general cleaning instructions of cargo body (1), refer to para. 2-8.

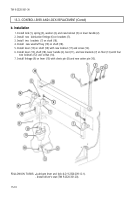

2. Inspect all screws, washers, and springs for defects. Replace if defective.

3. Inspect frame sills (4) for end splits or rotting. Replace if end split(s) exceeds width of frame sill or

frame sill is rotting.

4. Inspect cargo body (1) for structural damage or rust. Replace if damage or rust is severe and exceeds

available repair procedures.

c. Repair

1. Remove and install lashing hooks and/or data plates in area(s) to be repaired (TM 9-2320-361-20).

2. Remove paint and/or rust from area(s) to be welded or repaired (TM 9-237).

3. Repair cargo body (1) (TM 9-237 and TC 9-510).

4. Paint cargo body as necessary (TM 43-0139 and TB 43-0209).

d. Installation

WARNING

All personnel must stand clear during lifting operations. A swinging

or shifting load may cause injury to personnel.

NOTE

.

Use breaker bar to aline body and frame brackets.

●

Assistant will help guide cargo body during lifting operations.

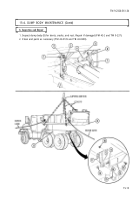

1. Place one frame sill (4) on each frame rail (5).

NOTE

Perform steps 2 and 3 if installing new cargo body.

2. Install cargo body dropside (2) (M35A2C) (TM 9-2320-361-20).

3. Install cargo body tailgate (3) (TM 9-2320-361-20).

4. Lift

cargo

body

(1) off supports and lower onto frame rails (5).

15-4

Back to Top