TM-9-2320-361-34 - Page 323 of 764

TM 9-2320-361-34

I

15-4. DUMP BODY MAINTENANCE (Contd)

I

a. Removal

WARNING

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Never work under dump body

until

safety braces are properly

positioned.

Injury or

death to personnel may occur if dump body

suddenly lowers.

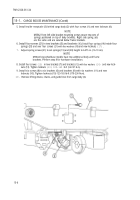

Remove two

lubrication

fittings

(1)

from two thrust plate pins (2).

Remove two locknuts

(5)

and

screws

(6)

from

two

thrust

plate

pins (2). Discard locknuts (5).

Lower

two safety braces (3).

CAUTION

Wooden supports must be able to hold weight of dump body.

NOTE

Ensure block support is in place before lowering dump body or

lockdown latch may latch on dump body.

Install wooden support between subframe (9) and dump body (8).

Lower dump body (8) onto wooden support.

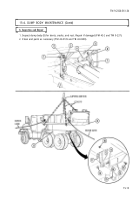

Attach two chains to four corners of dump body (8). Attach two guide lines to dump body (8).

Attach lifting device to chains and remove slack from chains.

WARNING

Ensure dump

control lever is in neutral at all times. Injury or death

to personnel may result if

lift

cylinder

is operated when not

secured.

Remove two thrust plate pins (2) from roller arms (7) and thrust plates (4).

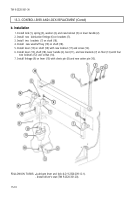

Remove twelve locknuts (10) and screws (12) from two hinge brackets (17) and dump body (8).

Discard locknuts (10).

Remove two locknuts (16) and screws (11) from two hinge brackets (17). Remove two hinge

brackets (17) from dump body (8) and pivot pins (14). Discard locknuts (16).

Remove two lubrication fittings (15) from pivot pins (14).

WARNING

All personnel must stand clear during lifting operations. A swinging

or shifting load may cause injury to personnel.

NOTE

Assistant will help guide dump body during lifting operations.

12. Raise dump body (8) clear of vehicle.

CAUTION

Wooden supports must be able to hold weight of dump body.

13. Lower dump body (8) and place on wooden supports.

14. Remove lifting device, two chains, and guide lines from dump body (8).

15-12

Back to Top