TM-9-2320-361-34 - Page 89 of 764

TM 9-2320-361-34

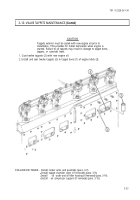

3-12. OIL PUMP MAINTENANCE

(Contd)

b. Inspection

1. Inspect gear (3) for damaged teeth or scored bearing surfaces. Remove minor burrs with fine mill

file. If damage is beyond repair, replace.

2. Inspect all tubes (7), (23), and (28) for dents, cracks, bent flanges, flattened areas, and cracked, torn,

or loose screen. If damaged, replace.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

3-38

Install gear (3) on oil pump (14) with nut (4).

Prime oil pump (14) with oil.

Install oil pump (14) on two bearing caps (1) with three new lockscrews (15), Tighten lock-

screws (15) 53-58 lb-ft (72-79 N.m).

Tighten nut (4) 44-46 lb-ft (60-62 N.m) and install new cotter pin (5).

Install new gasket (27) and scavenger tube (28) on oil pump (14) with two new lockwashers (35) and

screws (34). Tighten screws (34) 75-100 lb-in. (8-11 N.m).

Install two new lockwashers (29) and screws (30) on scavenger tube (28) and engine block (2).

Tighten screws (30) 150-175 lb-in. (17-20 N.m).

Install two screws (33) on scavenger tube (28) with two new lockwashers (32) and nuts (31). Tighten

nuts (31) 75-100 lb-in. (8-11 N.m).

Install brace (16) on oil pump (14) with two new lockwashers (19) and screws (20). Tighten screws (20)

75-100 lb-in. (8-11 N.m).

Install new gasket (26) and pickup tube (23) on oil pump (14) with two new lockwashers (25) and

screws (24). Tighten screws (24) 75-100 lb-in. (8-11 N.m).

Install screw (22) through pickup tube clamp (21) and brace (16) with new lockwasher (17) and

nut (18). Tighten nut (18) 75-100 lb-in. (8-11 N.m).

Install new packing (13) and flange (12) on outlet tube (7) and oil pump (14) with two new lock-

washers (11) and screws (10). Tighten screws (10) 75-100 lb-in. (8- 11 N.m).

Install new gasket (6) and outlet tube (7) on engine block (2) with two screws (9). Tighten screws (9)

150-175 lb-in. (17-20 N.m).

Install new safety wire (8) on screws (9).

Back to Top