TM-9-2320-361-34 - Page 83 of 764

TM9-2320-361-34

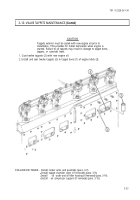

3-10. VALVE TAPPETS MAINTENANCE

THIS TASK COVERS:

a.

Removal

c. Installation

b. Cleaning and Inspection

INITIAL SETUP

APPLICABLE MODELS

All

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

MATERIALS/PARTS

Lubricating oil, OE/HDO 30

(Appendix C, Item 13)

REFERENCES (TM)

TM 9-2320-361-10

TM 9-2320-361-34P

TM 9-2815-210-34-2-2

EQUIPMENT CONDITION

●

Parking brake set (TM 9-2320-361-10).

●

Air

compressor

support removed (front only)

(para. 3-15).

●

Oil

cooler

and

oil

cooler filter housing removed,

front only (para. 3-14).

●

Tappet chamber cover removed (rear only)

(para. 3-9).

●

Rocker arms and pushrods removed (para. 3-7).

CAUTION

Camshaft and tappets are a matched set. All tappets removed must

be tagged for installation. Failure to do this may result in damage

to tappets or camshaft.

NOTE

Sludge from engine oil may build upon external surfaces of tappets.

When this condition exists, drycleaning solvent maybe applied to

tappets while working tappets up and down to loosen sludge and aid

removal.

Remove and tag twelve tappets (2) from tappet bores (1) in engine block (3).

b. Cleaning and

Inspection

1. For general cleaning instructions, refer to para. 2-8.

NOT E

Normal tappet and camshaft lobe wear is indicated by a slight inward

coning or dishing effect of the cam contact surface on tappets.

2. Inspect tappets (2) for coned, scored, or grooved cam contact. Minor surface coning is acceptable

when cam contact surface is free of grooving and scoring, otherwise replace.

3. Inspect machined sides of twelve tappets (2) for grooving or scoring. Replace if defective.

4.

If tappets (2) need replacement, inspect twelve tappet bores (1) and lobe surfaces of camshaft. Refer

to TM 9-2815-210-34-2-2 for inspection.

3-32

Back to Top