TM-9-2330-247-14-P - Page 162 of 320

TM 9-2330-247-14&P

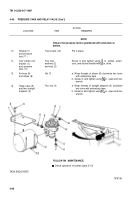

4-48.

RETRACTABLE SUPPORTS

This Task Covers:

a.

Removal

c.

Installation

b. Repair

Initial Setup:

Equipment Conditions:

Materials/Parts:

l Handbrakes applied (para 2-12).

l Grease (Item 8,

Tools/Test Equipment:

l Caps, vise, jaw

l Drift, brass,

~ in.

l Hammer, hand, ball-peen, 3 lb

l Handle, ratchet, ~ in. drive

l Pliers, slip-joint

l Puller/instalilr, cup

l Puller, seal

l Punch, X6 in.

l Punch, %6 in.

l Screwdriver, flat-tip, ~ in.

l Socket, ~ in. drive, 1~6 in.

s Trestle, motor vehicle, 10 ton

s Vise, machinist’s

l Wrench, adjustable, 10 in.

l Wrench, automotive, adjustable

l Wrench, box-end, %6 in.

l Wrench, box-end, lfi6 in.

l Wrench, torque, 0–200 Ib.-ft. range

Appendix E)

Personnel Required: Two

ACTION

LOCATION

ITEM

REMARKS

NOTE

Both retractable supports are replaced and repaired in the same way. This procedures is

for one; repeat for the other.

REMOVAL

1.

Frame (4)

2.

Square neck

bolt (11) and

nut (8)

Safety chain

plate (1)

Cotter pin (9)

a. Place trestle under front of trailer.

b. Lower retractable support to park position

(para 2-12).

c. Raise retractable support tire (2) off ground

(para 2-12).

Using slip-joint pliers, unbend and pull out.

4-108

Back to Top